-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

Top 10 Plastic Pipe Fittings You Need to Know About in 2026

In the evolving world of construction and plumbing, understanding the role of plastic pipe fittings is essential. Recent industry reports indicate that the global plastic pipe fittings market is projected to reach $12 billion by 2026. This growth reflects a notable shift towards materials that offer durability and cost-effectiveness. Plastic pipe fittings have become increasingly popular due to their lightweight nature and resistance to corrosion.

However, not all plastic fittings are created equal. Some may not withstand high-pressure systems effectively, leading to potential failures. It's crucial to recognize that while plastic pipe fittings offer many benefits, they can also present risks if improperly selected or installed. The decision-making process must include an assessment of quality standards.

Navigating this intricate market requires a closer look at the leading products. A key focus should be on reliable brands known for innovation and adherence to safety regulations. As we explore the top 10 plastic pipe fittings to know about in 2026, we'll highlight their unique features and common drawbacks. Thus, informed choices can lead to safer and more efficient plumbing systems.

Key Features of Modern Plastic Pipe Fittings in 2026

In 2026, modern plastic pipe fittings emphasize durability and flexibility. These features make them suitable for various applications. Advanced materials offer resistance to chemicals and temperature fluctuations. This ensures long-lasting performance in challenging environments. Enhanced designs now allow for easier installation and maintenance. Fittings are lightweight, making them easy to handle.

A notable trend is the increased use of sustainable materials. This shift addresses environmental concerns while maintaining quality. Many fittings are recyclable, reducing waste. However, some manufacturers still rely on traditional plastics. This inconsistency raises questions about overall sustainability.

The focus on innovation is clear. Improved sealing technologies prevent leaks effectively. Yet, not all fittings meet these new standards. Some still lack the necessary certifications for safety and performance. It’s crucial to research and choose wisely. Quality should not be sacrificed for cost.

Top 10 Plastic Pipe Fittings You Need to Know About in 2026

| Fitting Type | Material Type | Application | Temperature Range | Pressure Rating |

|---|---|---|---|---|

| PVC Elbow | PVC | Water Supply | -15°C to 60°C | 10 bar |

| CPVC Coupling | CPVC | Hot Water | 0°C to 93°C | 13 bar |

| Polyethylene Tee | PE | Gas Transport | -40°C to 60°C | 5 bar |

| PPR Fitting | PPR | Plumbing | 0°C to 95°C | 16 bar |

| Acid-Resistant Fitting | PVC-U | Chemical Processing | 0°C to 50°C | 10 bar |

| Hydraulic Fitting | Nylon | Hydraulic Systems | -20°C to 80°C | 15 bar |

| Swivel Nut | PP | Plumbing Connections | -10°C to 70°C | 12 bar |

| Saddle Tee | HDPE | Irrigation | -20°C to 50°C | 6 bar |

| Flange Adapter | PVC | Industrial Piping | -10°C to 60°C | 10 bar |

Top Materials Used in Plastic Pipe Fittings: Pros and Cons

Plastic pipe fittings come in various materials, each with its unique advantages and disadvantages. The most common materials include PVC, CPVC, and PEX. PVC is cost-effective and durable. It resists corrosion but struggles with UV exposure. CPVC can handle higher temperatures. However, it tends to be more brittle than PVC. PEX is flexible and resistant to freeze damage, yet it can be vulnerable to certain chemicals.

When choosing a material, consider your specific needs. PVC is great for drainage, while CPVC works well for hot water systems. PEX is excellent for residential plumbing. Remember that the right choice can greatly impact the longevity of your system.

Tips: Always check local building codes. They may dictate which materials you can use. Understand the environment your pipes will be in. Some materials are better for cold climates. Finally, factor in installation costs; sometimes cheaper materials can lead to higher repair bills later. Making an informed choice can save you time and money.

Most Common Types of Plastic Pipe Fittings and Their Applications

Plastic pipe fittings play a crucial role in various plumbing and construction tasks. They connect sections of piping, ensuring a secure and leak-free system. Among the most common types are elbow fittings, which change the direction of pipes. They help navigate around obstacles easily. Couplings are also essential; they join two pipe ends together. This is often necessary in repairs or expansions. Each fitting type serves a specific need.

In addition, tee fittings create branches in a piping system. They allow for multiple lines to be fed from a single source. Some people underestimate their importance, but these fittings are very effective. While working with plastic fittings, consider choosing the right material type. Different plastics provide varying levels of strength and flexibility. Mistakes can lead to significant issues down the line.

Another common fitting is the adapter, which transitions between different pipe materials. Whether it's plastic to metal or another combination, versatility is key. Additionally, threaded fittings can facilitate easy assembly. In my experience, not all fittings fit perfectly. One might find wrong sizes or shapes. This is critical when planning a project. Inadequate attention here often results in delays and extra costs.

Top 10 Plastic Pipe Fittings in 2026

Innovations in Design and Durability for 2026 Plastic Fittings

In 2026, plastic pipe fittings are set to undergo significant innovations in design and durability. Recent industry reports suggest that advancements in polymer technology will enhance strength and resistance against harsh environments. This includes improvements in UV resistance and temperature adaptability, making fittings more versatile for various applications.

Many manufacturers are focusing on sustainability. The push for eco-friendly materials has led to the development of recycled plastic fittings. According to industry trends, up to 30% of new fittings may be sourced from recycled materials by 2026. This change could reduce waste while maintaining functionality.

Tips: Always consider the environment when choosing fittings. Look for items that guarantee durability. Check if your fittings align with sustainability goals. Sometimes, products look appealing but may not perform well in real conditions. It’s vital to balance aesthetics with functionality.

Installation Tips and Best Practices for Plastic Pipe Fittings

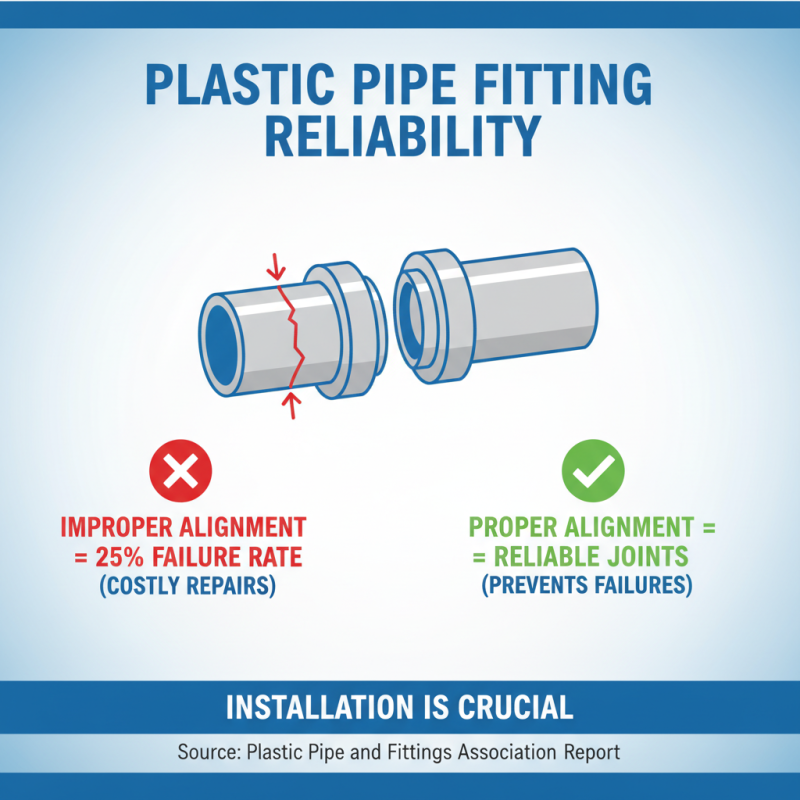

When working with plastic pipe fittings, installation is crucial for reliability. A report from the Plastic Pipe and Fittings Association notes that improper installation can lead to joint failures in up to 25% of cases. Proper alignment is essential. Misalignment can create stress points, leading to premature failures and costly repairs.

Use appropriate torque settings during installation to avoid over-tightening. Research indicates that 15% of plastic pipe fittings fail due to excessive force during installation. Remember to inspect each fitting for cracks or defects before use. Small imperfections often lead to bigger issues later. Regularly check your tools. Worn or damaged tools can compromise the integrity of fittings.

Sealing joints correctly is another vital aspect. Be cautious with sealant application. Using too much can lead to leaks, while too little may not create a secure seal. A study shows that improper sealing accounts for up to 30% of leaks in plastic plumbing systems. Aim to strike a balance for optimal results. Stay informed about new technologies and best practices to maximize efficiency.

Related Posts

-

Understanding the Essential Role of PE Pipe Fittings in Modern Plumbing Systems

-

2025 How to Choose the Right Pressure Pipe Fittings for Your Plumbing Needs

-

Top 5 Pressure Pipe Fittings You Need for Your Next Plumbing Project

-

How to Choose the Right Plastic Pipe Fittings for Your Plumbing Projects

-

How to Choose the Right HDPE Pipe Fittings for Your Project

-

2025 Top Trends in Plastic Pipework for Efficient Construction Solutions