-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

What is Poly Water Pipe? Benefits, Uses, and Installation Guide

Poly water pipe, often referred to as polyethylene pipe, has gained significant attention in various industries due to its unique properties and advantages. This versatile piping solution is made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), which makes it lightweight, durable, and resistant to corrosion and chemical damage. The increasing demand for reliable and efficient water supply systems has led to the widespread adoption of poly water pipe in residential, agricultural, and commercial applications.

One of the primary benefits of using poly water pipe is its flexibility, which allows for easy installation in various landscape conditions. Unlike traditional piping materials, poly water pipes can bend and adapt without the need for additional fittings, reducing labor costs and installation time. Furthermore, they have a smooth interior surface that promotes optimal flow and minimizes the likelihood of blockages, making them an ideal choice for transporting water over long distances.

In this article, we will explore the numerous benefits and uses of poly water pipe, outlining its versatility in different applications, and providing a comprehensive installation guide. Whether you are a homeowner looking to upgrade your water supply system or a contractor seeking reliable piping solutions, understanding the advantages of poly water pipe can help you make informed decisions for your projects.

What is Poly Water Pipe? Understanding its Composition and Properties

Poly water pipe, also known as polyethylene pipe, is made from high-density polyethylene (HDPE), which provides remarkable strength and durability. Its lightweight nature makes it easy to handle and transport, while its flexibility allows for installation in various environments, including rocky or uneven terrains. As a thermoplastic material, poly water pipe resists corrosion and can withstand a wide range of temperatures, making it suitable for both hot and cold water applications.

The properties of poly water pipe, such as its resistance to chemicals and UV radiation, enhance its longevity and reliability in various plumbing scenarios. Its smooth interior surface reduces friction loss, improving water flow efficiency. Additionally, the pipe is fusion-welded at joints, minimizing the risk of leaks and ensuring a secure connection that can withstand pressure. These characteristics make poly water pipe a preferred choice for agricultural irrigation systems, residential plumbing, and municipal water supply networks. Overall, its composition and properties contribute to its widespread use and effectiveness in fluid transport systems.

Key Benefits of Using Poly Water Pipe in Various Applications

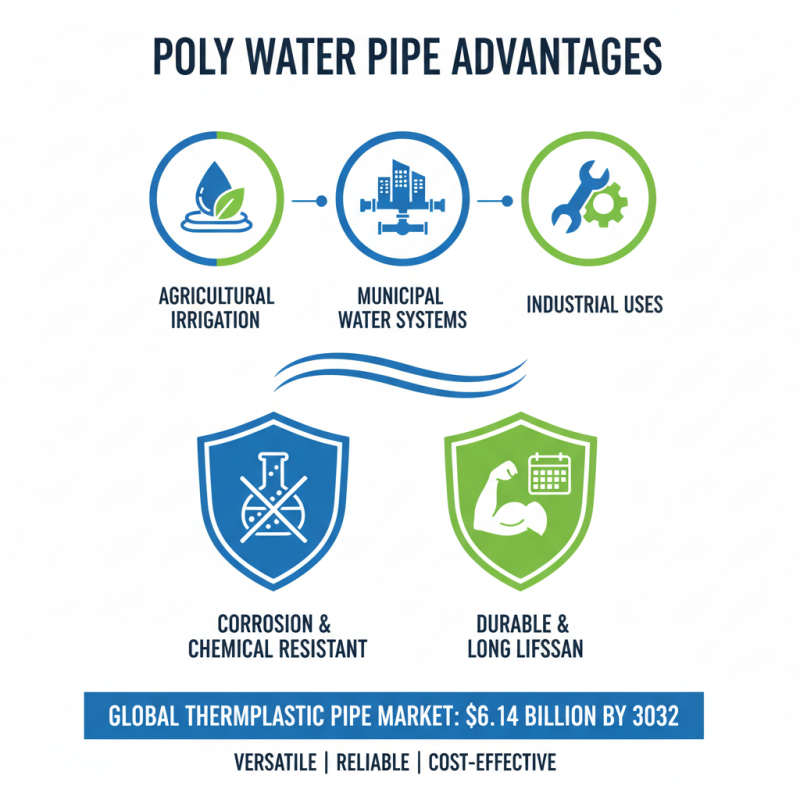

Poly water pipes have gained significant attention in recent years, particularly in the context of the growing thermoplastic pipe market projected to reach $6.14 billion by 2032. The versatility and durability of poly water pipes make them a top choice for various applications, from agricultural irrigation to municipal water systems. They are resistant to corrosion and chemical reactions, which extends their lifespan and reduces maintenance costs.

One of the key benefits of using poly water pipe is its lightweight nature. This property not only facilitates easier installation but also lowers transportation costs. Additionally, poly water pipes have excellent flexibility, allowing them to withstand pressure fluctuations and environmental stress. This adaptability is crucial in areas prone to land movement or soil expansion.

**Tips:** When installing poly water pipes, ensure that you have the right fittings and connectors to maintain a secure and leak-free system. Also, consider using heat fusion techniques for joints, which provide stronger, more reliable connections than traditional methods. Finally, always follow local guidelines and regulations for installation to ensure compliance and optimal performance.

Common Uses of Poly Water Pipe in Residential and Commercial Settings

Poly water pipes are increasingly popular in both residential and commercial settings due to their versatility and durability. Common applications include water supply lines, drainage systems, and irrigation setups. These pipes are especially advantageous for agricultural use, as they can easily be buried underground and withstand various environmental conditions, making them ideal for transporting water efficiently.

In residential areas, poly water pipes are often used for garden irrigation systems, helping homeowners maintain healthy lawns and gardens without excessive water waste. In commercial settings, these pipes serve critical roles in plumbing systems and industrial applications where reliable water supply and drainage are essential. Their resistance to corrosion and lightweight nature simplifies installation, allowing for quick and cost-effective solutions in any project.

Poly Water Pipe: Common Uses in Residential and Commercial Settings

Installation Guide for Poly Water Pipe: Step-by-Step Procedures

When installing poly water pipes, following a structured, step-by-step procedure is crucial for achieving a long-lasting and efficient irrigation or plumbing system. Begin by selecting the right size and type of poly pipe, often made from high-density polyethylene (HDPE), which offers exceptional durability and resistance to corrosion. According to the Plastics Pipe Institute, poly pipes can last over 50 years when installed properly under normal conditions, making them an excellent investment for both residential and agricultural applications.

Next, ensure you have the proper tools, including a pipe cutter, fittings, and a heat source if you are using welded joints. Start by marking the installation area and digging a trench to the required depth—typically, a depth of 12 to 18 inches is standard, depending on local frost lines.

After laying the pipe in the trench, make sure to secure it with approved fittings to prevent leaks; a study from the American Society of Civil Engineers indicates that well-fitted poly pipes have significantly lower failure rates compared to traditional materials. Finally, backfill the trench carefully, taking care not to damage the pipe and ensuring a proper slope for drainage. This meticulous approach not only enhances the lifespan of the installation but also optimizes the flow of water through the system.

Comparative Analysis: Poly Water Pipe vs. Traditional Piping Materials

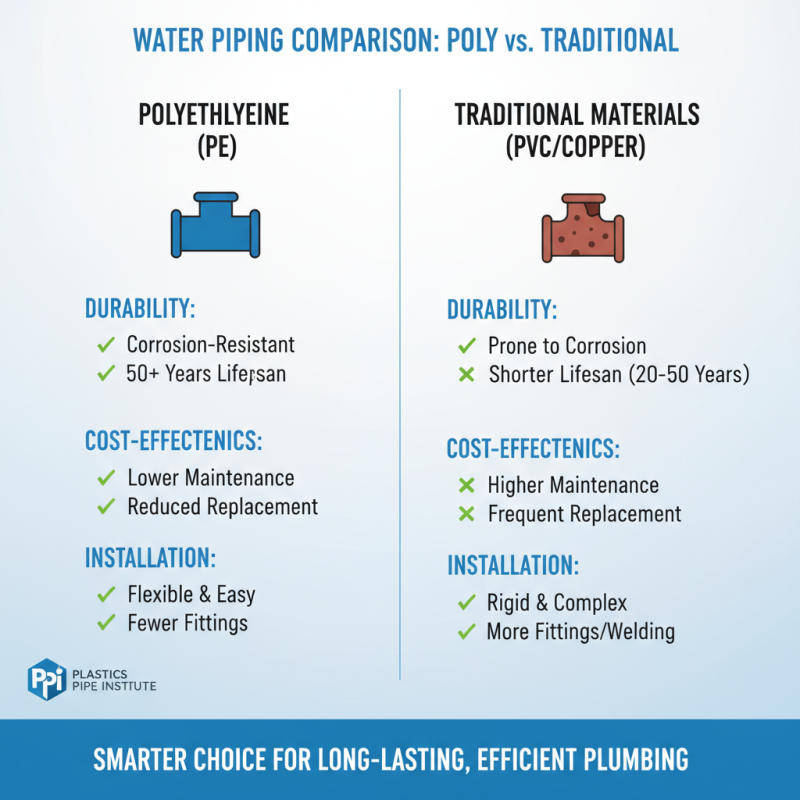

When comparing poly water pipes to traditional piping materials such as PVC and copper, several factors come into play including durability, cost-effectiveness, and installation convenience. Polyethylene (PE) pipes, commonly known as poly pipes, are flexible, resistant to corrosion, and have a long lifespan—often exceeding 50 years. According to a report by the Plastics Pipe Institute, the resistance of poly pipes to chemicals and environmental stress significantly decreases maintenance costs compared to metals, which can corrode and require more frequent replacement.

Additionally, the installation of poly water pipes is usually faster and less labor-intensive than traditional materials. A study from the American Society of Civil Engineers indicates that the lightweight nature of poly pipes allows for easier handling and requires less heavy equipment, effectively reducing installation durations by up to 30%. With their lower thermal conductivity, poly pipes also perform better in preventing issues such as condensation and freezing, making them a reliable choice in various climates. As more data highlights these advantages, the construction and plumbing industries are witnessing a gradual shift towards the adoption of poly water pipes over conventional materials.

Related Posts

-

Why Poly Water Pipe is the Best Solution for Your Irrigation Needs

-

Top 5 Essential Tips for Choosing the Best PE Fitting for Your Plumbing Needs

-

Top 5 Benefits of Using Poly Pipe for Your Irrigation and Plumbing Needs

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

10 Best PVC Water Pipes for Efficient Water Management in 2023