-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

Ultimate Guide to Poly Pipe Sizes for Your Next Project

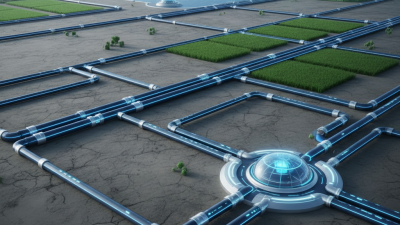

When embarking on a project that requires plumbing or irrigation systems, understanding the different poly pipe sizes is crucial for ensuring optimal functionality and efficiency. Polyethylene pipes, commonly referred to as poly pipes, are widely favored in various applications due to their durability, flexibility, and resistance to corrosion. However, with a variety of sizes available, selecting the right dimensions can often be a daunting task for both professionals and DIY enthusiasts alike.

This ultimate guide to poly pipe sizes will provide you with comprehensive insights into the various dimensions, specifications, and applications of these essential components. By determining the appropriate poly pipe sizes for your specific project requirements, you can enhance the overall performance of your system while avoiding common pitfalls associated with improper sizing. From understanding the nuances of pressure ratings to evaluating flow rates, this guide aims to equip you with the knowledge needed to make informed decisions that will contribute to the success of your project.

Understanding Poly Pipe: What is it and Its Common Uses

Polyethylene (PE) pipe, commonly known as poly pipe, is a flexible plastic piping solution widely used in various industries including agriculture, construction, and municipal applications. Characterized by its lightweight nature and resistance to corrosion, poly pipe has become a preferred choice for transporting water and other fluids. According to a report by the Plastics Industry Association, the global demand for polyethylene pipes is projected to grow at a robust rate of 4.5% annually, highlighting the increasing reliance on this material for critical infrastructure projects.

One of the most significant advantages of poly pipe is its versatility. It is available in a range of sizes and pressure ratings, making it suitable for applications such as irrigation systems, plumbing, and drainage systems. The American Society of Civil Engineers notes that poly pipe's attributes, such as its flexibility and durability, make it ideal for projects requiring a high degree of reliability under varying conditions. For example, in agricultural settings, the use of poly pipe has been linked to improved water efficiency, which is crucial in areas facing water scarcity. With advancements in manufacturing processes, the quality of poly pipes has improved significantly, leading to longer lifespans and reduced maintenance costs, confirming its role as a critical component in modern infrastructure development.

Types of Poly Pipe Sizes and Their Applications in Various Projects

When it comes to selecting the right poly pipe sizes for your projects, understanding the various types and their specific applications is crucial. Polyethylene pipes come in a range of diameters, typically measured in a standard format that includes the outer diameter and wall thickness. Common sizes range from ½ inch to 63 inches, with applications varying from irrigation systems in agriculture to potable water distribution in urban settings. According to industry reports, using the appropriate pipe size can lead to a reduction in material costs by approximately 15%, and can also enhance flow efficiency by over 20% in specific applications.

One key consideration in choosing the right poly pipe size is the pressure rating, which is crucial for the intended use—as higher pressure demands a thicker wall. For instance, a pipe rated for a higher pressure can withstand more stress, making it suitable for applications involving the transportation of liquids at elevated pressures. Additionally, different gauges may fit better in certain scenarios, such as low-pressure irrigation versus higher pressure mains.

Tips: Always assess the flow requirements and pressure capacities of your project before selecting a pipe size. Additionally, when installing poly pipe, consider the environmental conditions, as temperature fluctuations can affect the integrity of the material over time. Regular inspections and maintenance can help prevent potential failures in your piping system, ensuring longevity and reliability.

How to Choose the Right Poly Pipe Size for Your Needs

Choosing the right poly pipe size for your project is crucial to ensure efficiency and effectiveness. When selecting a poly pipe, factors such as flow rate, pressure requirements, and the intended application must be considered. According to the American Society for Testing and Materials (ASTM), poly pipe sizes typically range from ½ inch to 63 inches in diameter, with larger sizes often deemed necessary for industrial applications or extensive agricultural projects. Understanding the flow capacity of different pipe sizes can significantly impact your project's performance.

Tips: Always refer to the Hydraulic Institute’s guidelines for determining flow rates in specific pipe sizes. For instance, a 2-inch poly pipe can typically handle around 20 gallons per minute at moderate pressure, making it ideal for smaller irrigation systems. Additionally, consulting local building codes can ensure that you select a pipe that meets regional standards for safety and efficacy.

Furthermore, it's important to analyze the operating conditions of your project. Factors such as soil type, environmental conditions, and installation depth can all influence your pipe size choice. A recent study by the Irrigation Association highlighted that properly sizing pipes can enhance water distribution efficiency by up to 30%, showcasing the significant impact of informed decision-making on resource management.

Installation Considerations for Different Poly Pipe Sizes

When selecting the appropriate poly pipe size for your project, it is essential to consider the installation parameters that align with your specific requirements. Different sizes of poly pipes can impact not only the flow rate but also the overall efficiency of the installed system. For example, larger diameter pipes generally facilitate higher water flow, making them ideal for irrigation systems or large-scale water transport. However, accommodating such pipes may require additional space and support structures to ensure stability and integrity during operation.

Another crucial installation consideration is the temperature and pressure ratings of the chosen pipe size. Poly pipes come with varying pressure ratings, which should be matched to the expected operational conditions of the system. Installing pipes that exceed the required specifications could lead to leaks or bursts under pressure, while undersized pipes might not handle high flow demands, compromising the effectiveness of your system. Additionally, assessing the lay of the land, proximity to other utilities, and future expansion possibilities will ensure that the poly pipe installation aligns with both current needs and potential future developments.

Poly Pipe Sizes and Their Applications

Maintenance and Lifespan of Poly Pipe: What to Expect

When it comes to maintaining poly pipe, understanding its lifespan and upkeep needs is essential for any project. Polyethylene pipes are known for their durability, often lasting over 50 years under the right circumstances. However, factors such as environmental conditions, pressure levels, and UV exposure can significantly impact their longevity. Regular inspections and timely repairs are crucial to ensure optimal performance and prevent premature failures.

**Tips:** To prolong the lifespan of your poly pipe, it is advisable to install it underground or shield it from direct sunlight with protective materials. Additionally, monitor pressure levels to avoid excessive stress that can lead to leaks or breaks.

Regular maintenance checks can help identify issues before they escalate. Look for signs of wear and tear, such as cracking or discoloration, which might indicate UV damage or physical stress. By staying proactive with your maintenance routine, you can significantly enhance the functionality and efficiency of your poly pipe system.

**Tips:** Consider using a soft brush to clean the exterior of your pipes and avoid harsh chemicals that could degrade the material. Storing spare pipes in a shade-covered area can also extend their lifespan before installation.

Ultimate Guide to Poly Pipe Sizes for Your Next Project

| Pipe Size (inches) | ID (Inner Diameter) (mm) | OD (Outer Diameter) (mm) | Max Pressure (psi) | Lifespan (Years) | Typical Applications |

|---|---|---|---|---|---|

| 1 | 25.4 | 33.4 | 160 | 50+ | Irrigation, Water Supply |

| 1.5 | 38.1 | 48.0 | 160 | 50+ | Drainage, Agricultural |

| 2 | 50.8 | 60.0 | 160 | 50+ | Sewage, Pressure Applications |

| 3 | 76.2 | 89.0 | 160 | 50+ | Hydraulic Systems, Irrigation |

| 4 | 101.6 | 114.0 | 160 | 50+ | Conduits, Pumping Systems |

Related Posts

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

-

Exploring the Versatility of Black Plastic Pipe in Modern Infrastructure Solutions

-

2025's Top 5 HDPE Plastic Pipe Innovations for Efficient Water Management

-

Top 5 Essential Tips for Choosing the Best PE Fitting for Your Plumbing Needs

-

Why Poly Water Pipe is the Best Solution for Your Irrigation Needs

-

2025 Top Trends in Plastic Pipework for Efficient Construction Solutions