-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

2025 How to Choose the Right HDPE Pipe for Your Project

As the demand for durable and efficient piping solutions continues to rise, the importance of selecting the right HDPE pipe for your project cannot be overstated. Industry expert Dr. Emily Carter, a leading authority on polyethylene applications, emphasizes this necessity by stating, "Choosing the appropriate HDPE pipe is crucial for ensuring long-term reliability and performance in any infrastructure project." With its exceptional resilience against environmental stresses and superior corrosion resistance, HDPE (High-Density Polyethylene) piping has become the material of choice for a range of applications, from water supply systems to industrial uses.

When embarking on a project, decision-makers must navigate various factors, including pipe diameter, pressure ratings, and environmental conditions, to make informed choices. Understanding the technical specifications and benefits of HDPE pipes, as well as the specific needs of a given project, ultimately drives success. By considering factors such as longevity, cost-efficiency, and adaptability, stakeholders can leverage the advantages of HDPE pipes and ensure the longevity of their investments. In this guide, we will delve into essential aspects of selecting the perfect HDPE pipe to optimize project outcomes and elevate infrastructure standards.

Understanding HDPE Pipe Basics and Applications

High-Density Polyethylene (HDPE) pipes have become increasingly popular in various applications due to their durability and flexibility. These pipes are primarily used in water distribution, sewage systems, and gas distribution, with the global HDPE pipe market projected to reach USD 22.04 billion by 2025, according to a report by MarketsandMarkets. One of the fundamental advantages of HDPE is its resistance to corrosion and chemicals, which enhances its longevity, making it favorable for applications in harsh environments.

Understanding the basics of HDPE piping is essential for any project manager or contractor. The material is lightweight and easy to install, which can significantly reduce labor costs and project timelines. Additionally, HDPE pipes exhibit low thermal conductivity and can maintain a consistent flow even in extreme temperature conditions. The American Society for Testing and Materials (ASTM) has established several standards that govern the production and performance of HDPE piping, ensuring reliability and safety in its applications. These performance metrics support HDPE's suitability for high-pressure systems, often rated for use in pressure classes up to 200 psi, which is critical for maintaining efficient operations in municipal and industrial settings.

2025 How to Choose the Right HDPE Pipe for Your Project - Understanding HDPE Pipe Basics and Applications

| Pipe Diameter (inches) | Typical Applications | Material Grade | Pressure Rating (psi) | Standard Length (feet) |

|---|---|---|---|---|

| 2 | Water distribution | HDPE 3408 | 160 | 20 |

| 4 | Sewer systems | HDPE 3408 | 160 | 20 |

| 6 | Irrigation systems | HDPE 3608 | 100 | 40 |

| 8 | Drainage | HDPE 3710 | 80 | 40 |

| 10 | Industrial applications | HDPE 4710 | 160 | 40 |

Key Factors to Consider When Selecting HDPE Pipe

When selecting HDPE (High-Density Polyethylene) pipe for your project, several key factors should be taken into account to ensure optimal performance and longevity. First and foremost, consider the application for which the pipe will be used. Different applications may require varying pressure ratings, chemical resistances, and durability standards. For instance, pipes intended for potable water systems must meet stringent safety certifications, whereas those used in agricultural applications may prioritize flexibility and resistance to environmental stressors.

Another crucial factor is the pipe sizing and installation environment. Proper sizing affects not only the flow capacity but also the installation method, which can vary based on soil conditions, depth of installation, and the need for bendability. Additionally, understanding the environmental temperature and potential exposure to UV light or chemicals is essential, as these factors can influence the pipe’s material performance over time. By addressing these considerations, project managers can ensure that they select the most suitable HDPE pipe, maximizing both efficiency and durability throughout the pipeline's lifecycle.

Key Factors to Consider When Selecting HDPE Pipe

Evaluating Pipe Sizes and Pressure Ratings

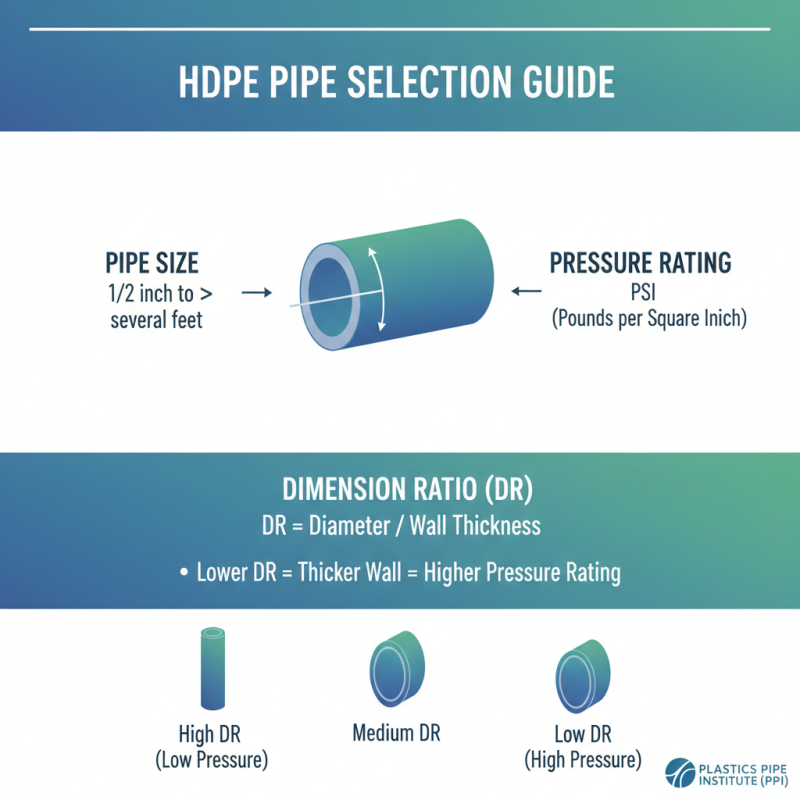

When selecting the right HDPE pipe for your project, evaluating pipe sizes and pressure ratings is critical to ensuring optimal performance and longevity. According to the Plastics Pipe Institute (PPI), the nominal pipe size (NPS) and the dimension ratio (DR) provide essential data for understanding the internal pressure capabilities of HDPE pipes. Typically, HDPE pipes are available in sizes ranging from ½ inch to several feet in diameter, with pressure ratings denoted in pounds per square inch (psi). The DR value, which is the ratio of the pipe's diameter to its wall thickness, directly influences the pipe's strength and flexibility.

Understanding the specific applications and system requirements is equally important when determining the appropriate pressure rating. For instance, a typical HDPE pipe with a DR of 11 can withstand pressures up to 160 psi, making it suitable for a range of applications, including potable water conveyance and irrigation systems. Additionally, the American Society for Testing and Materials (ASTM) standardizes these ratings, ensuring consistency across different manufacturers. In practical applications, engineers often rely on detailed pressure drop calculations, which consider flow rate, length, and diameter, to make informed decisions that align with the project’s demands and safety margins. Ultimately, choosing the right size and pressure rating is essential to ensure that the HDPE piping system operates efficiently and reliably throughout its service life.

Assessing Environmental Conditions for HDPE Usage

When selecting the right HDPE pipe for your project, understanding the environmental conditions where the pipe will be installed is critical. Factors such as soil type, temperature fluctuations, and moisture levels can significantly influence the longevity and performance of HDPE pipes. For instance, in areas with highly acidic soils, the pipe material may degrade faster, potentially leading to costly repairs or replacements. Additionally, temperature extremes can affect the flexibility and strength of the pipe, making it necessary to choose dimensions and grades that can withstand local climatic conditions.

**Tips:** Before finalizing your purchase, conduct a thorough assessment of the installation environment. Test soil conditions and review historical climate data to anticipate any challenges. Engaging with local engineers or environmental specialists can also provide invaluable insights into the best practices for HDPE usage in specific contexts.

Another essential factor to consider is the potential for environmental stressors such as ground movement, flooding, or chemical exposure. These stressors can impact the integrity of your pipes and their performance over time. Ensure that your HDPE selection is equipped to handle these situations by choosing thicker-walled pipes for high-stress applications or lines that may be submerged.

**Tips:** Always refer to local guidelines or consult with professionals regarding environmental assessments. This is crucial for determining the correct specifications and ensuring compliance with any regulations that may apply in your area.

Comparing Cost and Durability of Different HDPE Pipe Types

When selecting the appropriate HDPE pipe for your project, understanding the cost and durability differences among various types is crucial. High-Density Polyethylene (HDPE) pipes are renowned for their resistance to corrosion and flexibility. According to a report by the Plastic Pipes Conference Association, the lifespan of HDPE pipes can exceed 50 years, making them a cost-effective solution in the long run. While the initial investment might be higher compared to traditional materials, their longevity and reduced maintenance needs often offset these upfront costs.

The durability of HDPE pipes also comes into play when comparing different types. For instance, pipes designed for pressure applications typically feature thicker walls and enhanced material properties to withstand harsher conditions. A study from the American Water Works Association emphasizes that selecting pipes with higher density and specialized coatings can significantly improve performance, especially in abrasive environments. Additionally, while the average cost for standard HDPE pipe ranges from $0.80 to $3.00 per foot, specialty pipes can escalate to $5.00 or more, depending on the required specifications. Therefore, project managers must balance initial costs against anticipated service life and conditions when choosing the most suitable HDPE pipes.

Related Posts

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

Top 10 Benefits of High Density Polyethylene Pipe for Industrial Use

-

2025's Top 5 HDPE Plastic Pipe Innovations for Efficient Water Management

-

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions

-

Exploring the Benefits of HDPE Pipe: Why Its Durability and Chemical Resistance Make It an Industry Standard

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project