-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

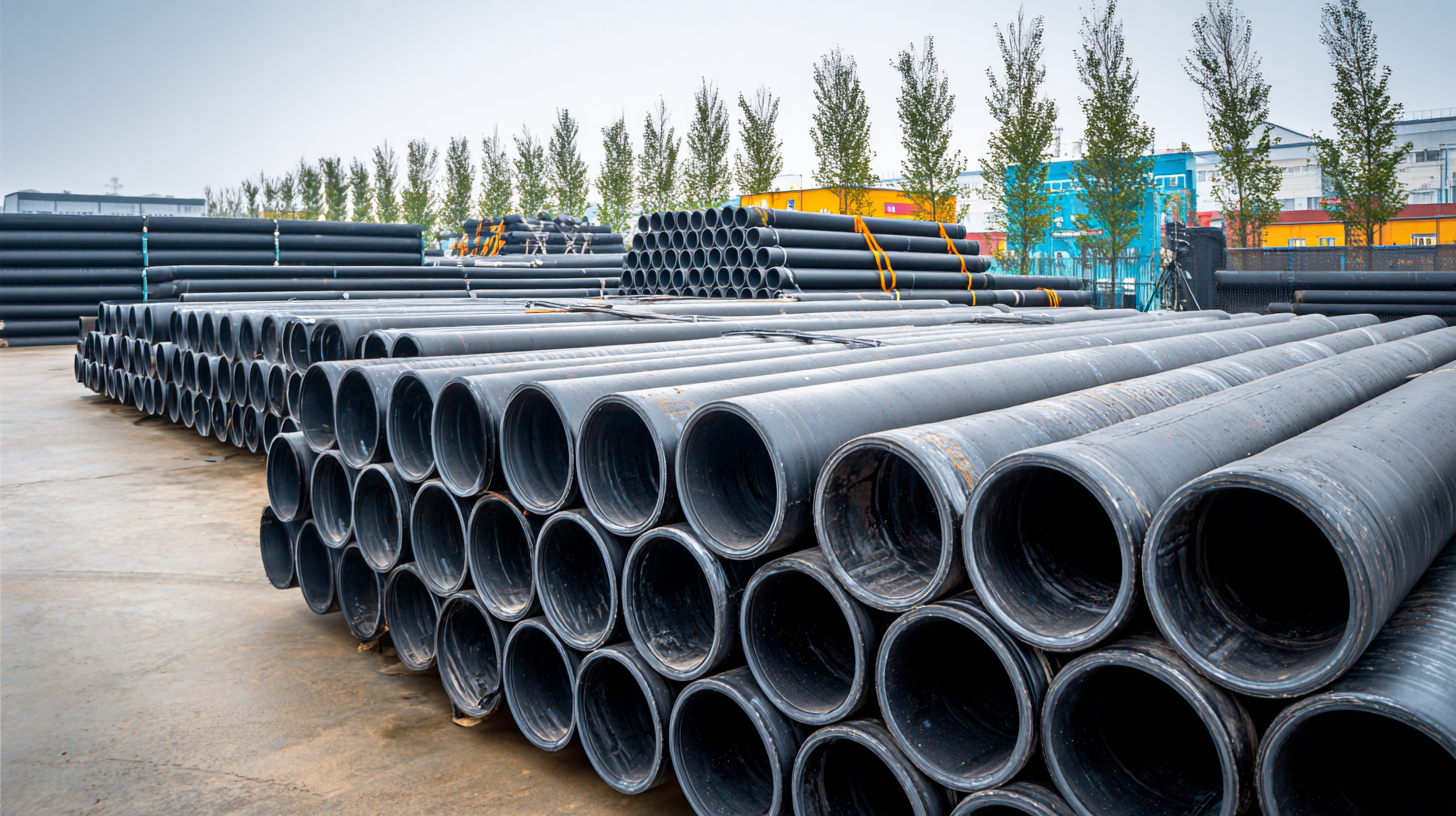

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions

In recent years, high density polyethylene pipe (HDPE) has emerged as a revolutionary material in modern infrastructure solutions, offering a myriad of advantages over traditional piping systems. According to a report by the Plastics Pipe Institute, HDPE pipes are known for their superior durability, flexibility, and resistance to corrosion, making them ideal for various applications such as water distribution, sewage systems, and industrial processes. The Global HDPE Pipe Market is projected to grow at a compound annual growth rate (CAGR) of 5% from 2023 to 2028, reflecting the increasing adoption of HDPE due to its cost-effectiveness and longevity. As municipalities and industries strive for sustainable solutions, the shift towards high density polyethylene pipe is not just a trend but a strategic move towards resilient and environmentally friendly infrastructure development.

Benefits of High Density Polyethylene Pipe in Water Management Systems

High-density polyethylene (HDPE) pipes have emerged as a pivotal solution in modern water management systems, driven by their unique characteristics and sustainability benefits. These pipes offer exceptional resistance to corrosion, which is vital in maintaining the integrity of water supply systems and ensuring the delivery of clean water. Their flexibility allows for easier installation in various terrains, supplemented by their lightweight nature, which reduces transportation costs and installation time. As urban areas expand and the demand for efficient water management grows, the adoption of HDPE pipes becomes increasingly essential.

High-density polyethylene (HDPE) pipes have emerged as a pivotal solution in modern water management systems, driven by their unique characteristics and sustainability benefits. These pipes offer exceptional resistance to corrosion, which is vital in maintaining the integrity of water supply systems and ensuring the delivery of clean water. Their flexibility allows for easier installation in various terrains, supplemented by their lightweight nature, which reduces transportation costs and installation time. As urban areas expand and the demand for efficient water management grows, the adoption of HDPE pipes becomes increasingly essential.

Moreover, the environmental advantages of HDPE pipes cannot be overlooked. As the industry moves towards sustainable practices, using recycled materials in HDPE pipe production is gaining traction, despite current regulations favoring virgin materials. This shift aligns with a broader commitment to reducing waste and promoting circular economy principles within the infrastructure sector. The expected growth of the HDPE pipes market, projected to reach USD 34.71 billion, underscores the importance of these materials in addressing both infrastructure needs and environmental challenges in water management systems.

Cost-Effectiveness of HDPE Pipe in Infrastructure Projects

High Density Polyethylene (HDPE) pipe has emerged as a game-changer in the realm of infrastructure projects due to its cost-effectiveness. One of the primary advantages is its long lifespan, which significantly reduces the need for frequent replacements. Unlike traditional materials that may corrode or deteriorate over time, HDPE is resistant to various environmental factors, allowing it to maintain its integrity and functionality for several decades. This durability translates to lower maintenance costs and reduced project expenditures over the long term, making HDPE an attractive option for budget-conscious infrastructure initiatives.

Moreover, the lightweight nature of HDPE pipe makes transportation and installation more efficient, reducing labor costs and project timelines. As these pipes can be easily handled and installed without heavy machinery, the overall operational expenses decrease. Additionally, the high flexibility of HDPE allows for installations in challenging terrains, further minimizing potential disruptions and costs associated with complex construction processes. By choosing HDPE pipe, infrastructure projects can leverage these economic advantages while ensuring the reliability and longevity of their systems.

Durability and Longevity of High Density Polyethylene in Harsh Environments

High Density Polyethylene (HDPE) pipes are increasingly recognized for their durability and longevity, making them an ideal choice for modern infrastructure, especially in harsh environments. These pipes exhibit remarkable resistance to various external factors, including chemical exposure, extreme temperatures, and intense pressure. The inherent properties of HDPE, such as its flexibility and toughness, allow it to maintain structural integrity under challenging conditions, which is essential for applications ranging from water supply systems to sewage management.

As the market for HDPE pipes is projected to reach USD 25.68 billion by 2029, it is evident that their advantages are being acknowledged across various sectors. This growing demand highlights the importance of HDPE in improving the resilience of infrastructure projects. Furthermore, ongoing research is enhancing materials used in conjunction with HDPE, such as improving low-temperature toughness in polypropylene, which can lead to even more robust and reliable solutions in civil engineering and construction. The evolution of these materials signifies a promising future for sustainable infrastructure development.

Advantages of High Density Polyethylene Pipe in Harsh Environments

Environmental Impact and Sustainability of HDPE Pipe Solutions

High Density Polyethylene (HDPE) pipes are gaining significant attention in modern infrastructure solutions due to their remarkable environmental impact and sustainability features. These pipes are highly durable and resistant to corrosion, which extends their lifespan and reduces the need for frequent replacements. This aspect is particularly beneficial for water supply systems and wastewater management, where maintaining infrastructure integrity is critical for environmental protection. The longevity of HDPE pipelines translates to lower resource consumption and reduced waste, aligning with global sustainability goals.

Moreover, the production of HDPE pipes involves processes that can be optimized for minimal environmental impact. As industries and consumers shift toward more sustainable materials, the adoption of HDPE in various applications, such as packaging and construction, underscores its potential to reduce carbon footprints. The recent initiatives to introduce recyclable HDPE products, like toothpaste tubes, demonstrate a growing commitment to circular economy principles, further enhancing the material's appeal in contemporary markets. As stakeholders increasingly value sustainable practices, HDPE pipes represent a viable solution for future infrastructure projects that prioritize both functionality and environmental responsibility.

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions - Environmental Impact and Sustainability of HDPE Pipe Solutions

| Aspect | Details |

|---|---|

| Material Composition | Made from polymerized ethylene, offering high resistance to corrosion and chemicals. |

| Lifespan | Can last over 50 years with minimal maintenance, reducing the need for replacements. |

| Environmental Impact | Recyclable material, contributing to a circular economy and minimizing landfill waste. |

| Installation Benefits | Lightweight and flexible, facilitating easier handling and installation processes. |

| Cost Efficiency | Lower lifetime costs due to durability and reduced maintenance requirements. |

| Water Conservation | Minimized leaks and optimal flow characteristics help conserve water resources. |

| Temperature Resistance | Suitable for a broad temperature range, making it versatile for various climates. |

| Resistance to Biofouling | Non-toxic and non-leaching properties reduce the risk of biofouling in water applications. |

Versatility of High Density Polyethylene in Various Infrastructure Applications

High Density Polyethylene (HDPE) has emerged as a cornerstone material in modern infrastructure, celebrated for its exceptional versatility across various applications. From water supply systems to sewage pipelines, HDPE's adaptability allows it to meet the specific needs of different projects with ease. Its resistance to corrosion and chemicals ensures that it can withstand the harsh environments often encountered in urban infrastructure settings. Moreover, the lightweight nature of HDPE facilitates easier handling and installation, reducing both labor costs and construction time.

High Density Polyethylene (HDPE) has emerged as a cornerstone material in modern infrastructure, celebrated for its exceptional versatility across various applications. From water supply systems to sewage pipelines, HDPE's adaptability allows it to meet the specific needs of different projects with ease. Its resistance to corrosion and chemicals ensures that it can withstand the harsh environments often encountered in urban infrastructure settings. Moreover, the lightweight nature of HDPE facilitates easier handling and installation, reducing both labor costs and construction time.

Tips: When considering HDPE for your infrastructure project, be sure to evaluate the specific environmental conditions it will face. Additionally, selecting the right size and thickness can significantly influence the longevity and performance of the pipe. Consulting with industry experts can provide valuable insights to optimize your material choices.

Another application demonstrating the versatility of HDPE is in stormwater management systems. Its flexible design enables it to adapt to various layouts and terrains, making it an ideal choice for sustainable drainage solutions. In addition, the longevity of HDPE pipes considerably minimizes maintenance costs, ensuring a reliable infrastructure for years to come.

Tips: Ensure proper jointing techniques are applied to enhance the integrity of HDPE installations. Regular inspections and maintenance checks can also help in identifying potential issues early, thus prolonging the life of the infrastructure.

Related Posts

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

Understanding the Essential Role of PE Pipe Fittings in Modern Plumbing Systems

-

Understanding the Role of Polyethylene Pipe in Sustainable Water Management Practices

-

The Ultimate Guide to PVC Pipes and Fittings: Exploring Benefits, Standards, and Market Trends

-

Exploring the Versatility of Black Plastic Pipe in Modern Infrastructure Solutions