-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

How to Choose the Right Plastic Pipe Fittings for Your Plumbing Projects

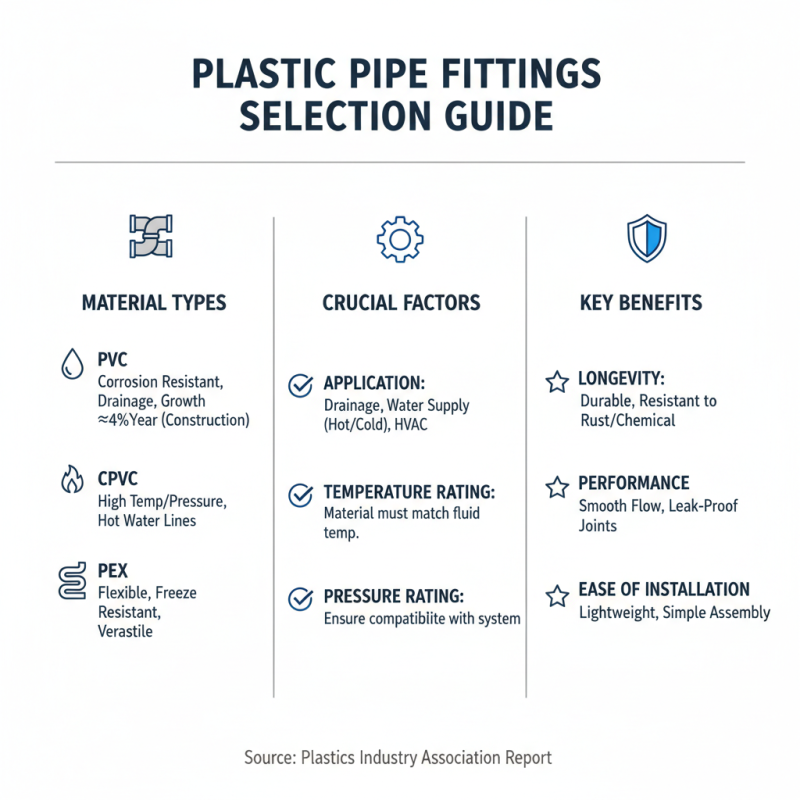

In the realm of plumbing, the selection of appropriate plastic pipe fittings is crucial for ensuring longevity and efficiency. According to the Plastics Industry Association, the market for plastic pipe fittings is projected to grow significantly, with an estimated compound annual growth rate (CAGR) of 4.5% over the next five years. This growth is largely attributed to the increasing demand for sustainable and lightweight materials in construction projects. A proper understanding of the types, applications, and specifications of plastic pipe fittings can empower professionals and DIY enthusiasts alike to make informed decisions that align with industry standards.

Renowned plumbing expert, Dr. Marcus Hargrove, emphasizes the importance of choosing the right fittings by stating, "The integrity of a plumbing system relies heavily on the quality and compatibility of its fittings; neglecting this can lead to costly repairs and inefficiencies." His insights highlight a crucial aspect of plumbing: inadequate fittings can compromise the entire system, leading to leaks and failures. Therefore, understanding the different types of plastic pipe fittings, such as PVC, CPVC, and PEX, along with their respective properties and best applications, will equip individuals with the knowledge needed to excel in their plumbing projects. With the right information and expertise, the journey to optimal plumbing efficiency begins with the prudent selection of plastic pipe fittings.

Understanding Different Types of Plastic Pipe Fittings in Plumbing

When it comes to plumbing projects, selecting the right type of plastic pipe fittings is crucial for ensuring longevity and reliability in your plumbing system. There are several common types of plastic pipe fittings, each designed to accommodate different applications and piping systems. For instance, PVC (polyvinyl chloride) fittings are widely used due to their durability and resistance to corrosion, making them ideal for cold water applications and drainage systems. On the other hand, CPVC (chlorinated polyvinyl chloride) fittings are suitable for hot water systems as they can withstand higher temperatures.

Another popular option is PEX (cross-linked polyethylene) fittings, known for their flexibility and ease of installation. PEX fittings can expand and contract without cracking, which makes them a great choice for regions with fluctuating temperatures. Additionally, the design of PEX fittings often allows for quick connections, reducing installation time. Understanding these various types of plastic pipe fittings and their specific uses will help you make informed decisions that ensure your plumbing projects are efficient and effective.

Plastic Pipe Fittings Usage in Plumbing Projects

Factors to Consider When Choosing Plastic Pipe Fittings

When choosing plastic pipe fittings for plumbing projects, several crucial factors should be considered to ensure optimal performance and longevity. First, it's important to assess the type of plastic material used in the fittings. Common materials include PVC, CPVC, and PEX, each offering unique advantages. For instance, PVC is known for its resistance to corrosion and is often used in drainage applications. According to a report by the Plastics Industry Association, the market for PVC fittings is projected to grow by around 4% annually, driven by increased demand in construction and infrastructure. Understanding the specific properties of these materials can guide selections that suit the intended application, particularly in terms of temperature and pressure ratings.

Another key consideration is compatibility with existing piping systems. When integrating new fittings, it's vital to ensure they match the diameter, pressure rating, and material specifications of the existing pipes. Failure to ensure compatibility can lead to leaks and system failures, which may incur significant repair costs. A 2022 study from the American Society of Plumbing Engineers highlights that improper fittings can account for nearly 20% of common plumbing issues faced by homeowners. Additionally, attention should be paid to local building codes and regulations, as certain materials and sizes may be mandated or restricted based on regional building practices. By carefully evaluating these factors, homeowners and contractors can make informed decisions that enhance the reliability and efficiency of their plumbing systems.

Evaluating Compatibility with Existing Plumbing Systems

When selecting plastic pipe fittings for your plumbing projects, one of the crucial factors to consider is their compatibility with your existing plumbing systems. This ensures that the fittings will work seamlessly with current pipes, preventing potential leaks or failures that could arise from mismatched materials. Understanding the specifics of your current plumbing—such as the type of materials used, the size and dimensions of existing pipes, and the intended application—is essential. For instance, if your current system comprises PVC pipes, using PVC fittings is advisable, as different materials can react negatively to one another or may not seal properly, leading to significant issues down the line.

Additionally, you should assess the pressure requirements and environmental factors that may influence your choice of fittings. Some systems operate under higher pressures and may necessitate fittings that can withstand these conditions, while others may be more flexible. It’s also important to consider temperature fluctuations, especially in extreme climates, and choose fittings that can handle these variations without degrading. By carefully evaluating these aspects of compatibility, you can ensure a reliable and efficient plumbing system that meets your project’s needs.

How to Choose the Right Plastic Pipe Fittings for Your Plumbing Projects

| Fitting Type | Material | Diameter (inches) | Pressure Rating (PSI) | Temperature Rating (°F) | Connection Type |

|---|---|---|---|---|---|

| Elbow | PVC | 2 | 120 | 140 | Slip |

| Tee | CPVC | 1.5 | 150 | 180 | Threaded |

| Coupling | Polyethylene | 3 | 100 | 100 | Socket |

| Reducer | PVC | 2 - 1 | 120 | 140 | Slip |

Assessing Quality and Durability of Plastic Pipe Fittings

When selecting plastic pipe fittings for your plumbing projects, assessing quality and durability is crucial to ensure a long-lasting and efficient installation. Quality plastic fittings are typically made from materials resistant to corrosion and UV exposure, which makes them suitable for both indoor and outdoor applications. Look for fittings that comply with industry standards to guarantee they can withstand high pressure and temperature fluctuations. It's essential to consider the type of plastic used, as different materials have varying levels of durability; for instance, PVC is known for its strength, while CPVC offers higher temperature resistance.

Moreover, a rigorous evaluation of the manufacturing process can provide insight into the durability of the fittings. Fittings that undergo stringent quality control measures during production tend to exhibit superior performance. Pay attention to the visual aspects as well; any signs of discoloration, warping, or imperfections may indicate lower product quality. Ultimately, ensuring that you choose high-quality plastic pipe fittings will lead to a plumbing system that not only functions effectively but also minimizes the risk of leaks and replacements in the future.

Installation Tips for Successful Plumbing Projects with Plastic Fittings

When embarking on plumbing projects that utilize plastic pipe fittings, it’s essential to understand the unique installation requirements of these materials. Plastic fittings are lightweight and easy to handle, but proper preparation is crucial to ensure a leak-free system. Begin by cleaning the pipes and fittings thoroughly to remove any dirt or debris that could compromise the seal. Utilizing a pipe cleaner or a similar tool can enhance the bond when using solvent cement.

Additionally, pay close attention to the temperature and humidity during installation. Extreme temperatures can impact the integrity of the fittings and the adhesive. It's advisable to work in moderate conditions, ideally around room temperature, to allow the adhesive to set properly. After applying solvent cement, hold the fittings in place for a few seconds to ensure a tight fit, and allow adequate curing time before pressurizing the system.

Lastly, always double-check the compatibility of your plastic fittings with the types of pipes you are using. Different plastics have varying chemical properties, which can affect the durability of the joint. Familiarizing yourself with the specifications of each component will help you avoid potential pitfalls and ensure a successful plumbing project. By following these tips, you can enhance the efficiency and longevity of your plumbing systems.

Related Posts

-

Understanding the Essential Role of PE Pipe Fittings in Modern Plumbing Systems

-

Top 5 Essential Tips for Choosing the Best PE Fitting for Your Plumbing Needs

-

2025 How to Choose the Right Pressure Pipe Fittings for Your Plumbing Needs

-

What is Poly Water Pipe? Benefits, Uses, and Installation Guide

-

Exploring the Benefits of HDPE Pipe: Why Its Durability and Chemical Resistance Make It an Industry Standard

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure