-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

How to Choose the Right HDPE Pipe Fittings for Your Project

Choosing the right HDPE pipe fittings for your project is a crucial step that can significantly influence the overall efficiency and longevity of your piping system. High-Density Polyethylene (HDPE) has become a popular choice due to its durability, flexibility, and resistance to a wide range of chemicals. However, with various options available on the market, the selection of appropriate HDPE pipe fittings can be daunting for many project managers and engineers. Understanding the specific requirements of your project, including the type of fluid being transported, pressure ratings, and environmental conditions, is essential in making an informed decision.

Moreover, the compatibility of HDPE pipe fittings with existing systems and components can impact installation and maintenance efforts. It is vital to consider factors such as fitting design, jointing methods, and installation practices to ensure a seamless integration within your project. By educating yourself on the types and specifications of HDPE pipe fittings, you can avoid common pitfalls and ensure that your piping system operates efficiently and safely over its intended lifespan. This guide will help you navigate the complexities of selecting the right HDPE pipe fittings, empowering you to make choices that best suit your specific project needs.

Understanding HDPE Pipes and Fittings: Basics and Applications

HDPE (High-Density Polyethylene) pipes and fittings have become increasingly popular in various applications due to their exceptional strength, flexibility, and resistance to corrosion. According to a report published by the Plastic Pipe Institute, the global demand for HDPE pipes is projected to reach 8.4 million tons by 2025, driven by infrastructure improvements and the expansion of urban areas. This versatile material effectively handles a wide range of fluids, from potable water to wastewater, making it a reliable choice for both municipal and industrial projects.

Understanding the applications of HDPE fittings is crucial in selecting the right components for any project. HDPE fittings can be used in numerous settings, including agricultural irrigation, chemical processing, and telecommunications. The American Society for Testing and Materials (ASTM) standards highlight the importance of selecting fittings that match the size and pressure rating of the pipes they connect. Fittings such as elbows, tees, and couplings must also assess not just the fluid they will carry, but also environmental factors, as UV exposure and temperature changes can affect performance. Thus, when choosing HDPE pipe fittings, it is essential to consider application-specific requirements to ensure a long-lasting and efficient system.

Factors to Consider When Selecting HDPE Pipe Fittings

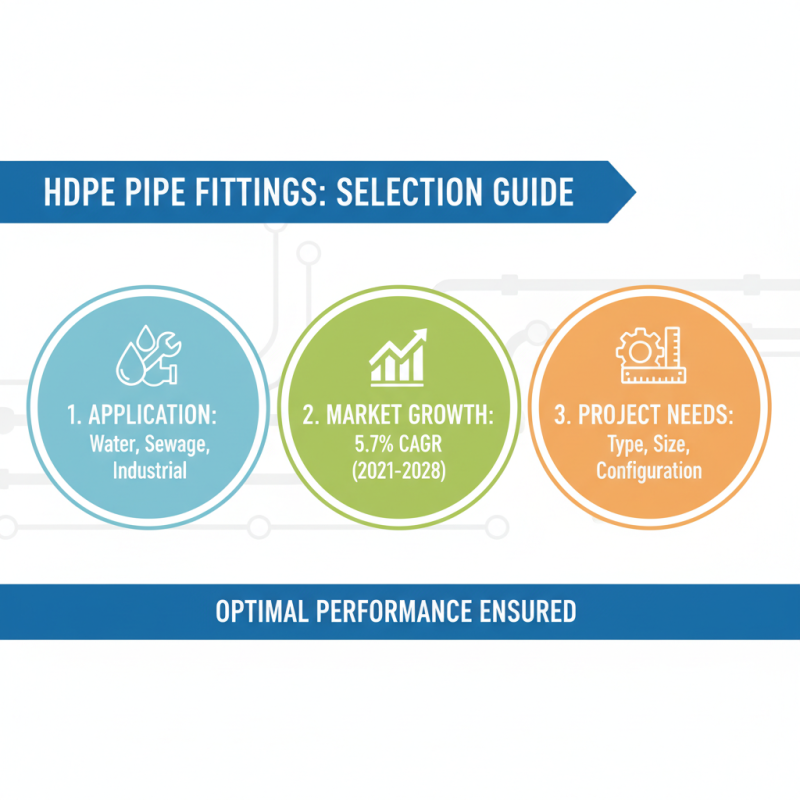

When selecting HDPE pipe fittings for your project, several factors warrant careful consideration. The first critical aspect is the application of the fittings. HDPE fittings are often utilized in various sectors, including water distribution, sewage systems, and industrial applications. According to a recent industry report by Reports and Data, the global demand for HDPE pipe fittings is projected to grow at a compound annual growth rate (CAGR) of approximately 5.7% between 2021 and 2028. Understanding the specific requirements of your project will help in choosing the right type, size, and configuration of fittings, ensuring optimal performance.

Another fundamental factor is the compatibility of the fittings with the HDPE pipes being used. It’s essential to verify that the fittings are designed to work with the specific pressure ratings and environmental conditions of your application. The American Society for Testing and Materials (ASTM) outlines various standards for HDPE pipe and fittings, emphasizing the importance of proper jointing techniques, which can significantly impact the longevity and reliability of the system. Additionally, considerations such as temperature resistance and chemical compatibility should not be overlooked, particularly in industrial settings where exposure to harsh chemicals is common. Overall, meticulous attention to these factors will ensure a well-functioning HDPE piping system that meets project demands.

Types of HDPE Pipe Fittings: Features and Benefits

When selecting HDPE pipe fittings for a project, understanding the various types available can significantly influence both performance and project efficiency. HDPE fittings traditionally include couplings, elbows, tees, and reducers, each serving unique purposes in pipeline systems. For instance, couplings are essential for joining lengths of pipe, while elbows facilitate directional changes in the system. According to the Plastic Pipe Institute, the use of HDPE fittings can lead to a reduction in leakage rates, which are reported to be as low as 0.5% compared to traditional materials.

In addition to the structural benefits, the features of HDPE pipe fittings contribute to their growing popularity. They are resistant to corrosion, abrasion, and chemical exposure, making them ideal for use in various industries, including water supply, wastewater treatment, and agricultural applications. Recent market analyses indicate that the global HDPE fittings market is expected to grow at a CAGR of 5.5% from 2021 to 2026, driven by the increasing demand for durable and environmentally friendly piping solutions. The lightweight nature of HDPE fittings allows for easier handling and installation, potentially reducing labor costs and installation time by up to 30%, as highlighted in the report by ResearchAndMarkets.

How to Choose the Right HDPE Pipe Fittings for Your Project - Types of HDPE Pipe Fittings: Features and Benefits

| Type | Features | Benefits |

|---|---|---|

| Elbow Fittings | Allows directional changes in piping | Minimizes pressure loss at bends |

| Tee Fittings | Connects three separate pipe lines | Facilitates branching of pipelines |

| Couplings | Joins two pipes together | Provides secure joints |

| Caps | Covers the end of a pipe | Prevents flow leakage |

| Reducers | Connects pipes of different diameters | Reduces flow rate effectively |

Installation Guidelines for HDPE Pipe Fittings

When installing HDPE pipe fittings, adhering to proper guidelines is crucial for ensuring system integrity and longevity. The first step is to verify the compatibility of the fittings with the pipes being used, as incompatible materials can lead to premature failure. According to a report from the Plastics Pipe Institute, improper installation techniques can account for up to 25% of failures in piping systems, highlighting the importance of following industry standards.

Once compatibility is confirmed, prepare the installation area by ensuring that the fittings and pipes are clean and free from dirt and debris. Proper alignment is also essential; fittings should not be forced into place but rather gently adjusted to avoid stress concentrations that could lead to leaks. Furthermore, temperature considerations play a significant role, as HDPE materials expand and contract with thermal changes. The American Society for Testing and Materials (ASTM) recommends maintaining a proper temperature range during installation to ensure optimal performance.

Finally, when joining HDPE fittings, it is essential to use appropriate fusion methods, such as butt or electrofusion, to create a strong and leak-free connection. Research indicates that when properly fused, HDPE joints can achieve near-identical strength to that of the pipe itself, significantly enhancing the overall reliability of the system. By following these installation guidelines, project managers can minimize risks related to failures and ensure that their HDPE piping systems operate efficiently for years to come.

Common Mistakes to Avoid in Choosing HDPE Pipe Fittings

When selecting HDPE pipe fittings for your project, avoiding common mistakes can greatly influence both the performance and longevity of your piping system. One frequent error is neglecting the compatibility of fittings with the specific HDPE pipe being used. According to the Plastic Pipe Institute, the proper alignment of pipe dimensions, as well as ensuring that the fittings match the nominal pipe sizes, is crucial to maintaining the integrity of the connection. An incompatible fitting can lead to leaks or failures under pressure, costing time and resources for repairs.

Another common pitfall is overlooking the environmental conditions where the pipes and fittings will be installed. HDPE fittings are available in various grades, designed to withstand specific chemical exposures and temperature ranges. The American Society for Testing and Materials (ASTM) highlights that using lower-grade materials in aggressive environments can lead to degradation over time, impacting the overall system. Furthermore, factors such as UV exposure and ground movement should also be considered, as they can affect the reliability and durability of the fittings used in the project. Properly evaluating these elements can significantly enhance the performance and lifespan of the HDPE piping system.

Related Posts

-

Top 10 Best PE Fittings for Durable Plumbing Solutions in 2023

-

Exploring the Versatility of Black Plastic Pipe in Modern Infrastructure Solutions

-

Top 5 Pressure Pipe Fittings You Need for Your Next Plumbing Project

-

What is Poly Water Pipe? Benefits, Uses, and Installation Guide

-

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions

-

Understanding the Versatility of 50mm PVC Pipe in Modern Plumbing Solutions