-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

Why Choose HDPE Water Pipe for Your Next Plumbing Project?

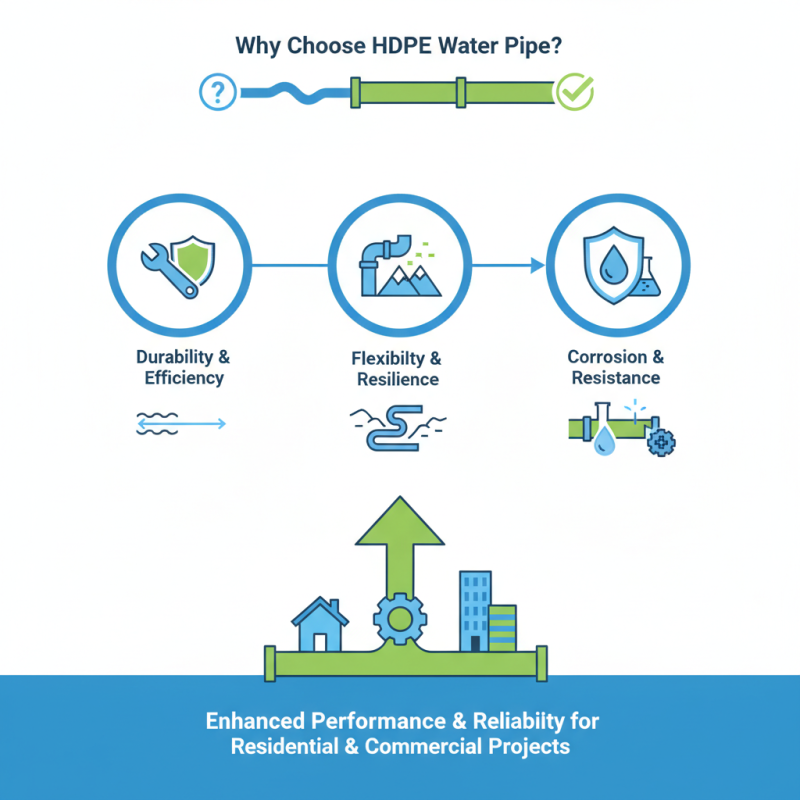

When it comes to plumbing projects, selecting the right materials is crucial for ensuring durability and efficiency. Among numerous options available in the market, HDPE water pipe stands out as a leading choice for both residential and commercial applications. Known for its remarkable strength and resistance to various environmental factors, HDPE (High-Density Polyethylene) water pipe offers a reliable solution for transporting water, making it an ideal choice for those looking to invest in long-lasting plumbing infrastructure.

One of the key benefits of HDPE water pipe is its exceptional flexibility, allowing it to be installed in a variety of challenging terrains without the risk of cracking or breaking. This resilience greatly reduces the need for frequent repairs or replacements, thereby saving both time and money in the long run. Furthermore, HDPE water pipe is also resistant to corrosion and chemical leaching, ensuring the safety and purity of the water supply.

In summary, whether you're planning a new plumbing installation or upgrading an existing system, opting for HDPE water pipe can significantly enhance the overall performance and reliability of your plumbing project. Its proven track record in various applications makes it a preferred material for savvy homeowners and contractors alike, highlighting the importance of making informed decisions for quality plumbing systems.

Advantages of HDPE Water Pipes in Plumbing Applications

High-Density Polyethylene (HDPE) water pipes have rapidly gained popularity in plumbing applications due to their impressive durability and flexibility. According to a report by the Plastics Pipe Institute, HDPE pipes have a tensile strength that is approximately twice that of conventional PVC pipes, making them highly resilient to impacts and environmental stresses. This strength translates into a longer lifespan, with HDPE pipes typically lasting up to 50 years or more under proper conditions. Furthermore, HDPE's corrosion resistance ensures that pipes remain intact even in aggressive environments, reducing the risk of leaks and failures.

Another significant advantage of HDPE water pipes is their ease of installation and versatility. The lightweight nature of HDPE allows for quicker handling and less labor intensity, as it can be easily transported and moved on-site. Studies show that utilizing HDPE can cut installation time by up to 30% compared to traditional piping materials. Additionally, HDPE's flexibility allows for a wide range of applications, including both underground and above-ground installations, making it ideal for diverse plumbing projects. Its ability to withstand extreme temperatures, from -40°F to 140°F, further enhances its feasibility in various climates, proving to be a reliable choice for modern plumbing solutions.

Durability and Longevity of HDPE Materials Compared to Alternatives

When considering materials for plumbing projects, the choice of HDPE (High-Density Polyethylene) water pipes stands out, particularly due to their exceptional durability and longevity compared to alternative options. According to a report by the Plastic Pipe Institute, HDPE pipes can have a lifespan exceeding 100 years, significantly outpacing traditional materials such as PVC and concrete, which typically last only 30 to 50 years. This impressive durability is attributed to the excellent corrosion resistance and flexibility of HDPE, making it suitable for a variety of environmental conditions.

Moreover, HDPE's resistance to environmental stressors, including temperature fluctuations and chemical exposure, enhances its longevity. A comparative study conducted by the American Water Works Association indicates that HDPE maintains structural integrity in challenging conditions, resulting in lower maintenance needs and reduced long-term costs for plumbing systems. This resilience not only minimizes the frequency of replacements but also contributes to better sustainability practices in construction, as fewer materials are discarded over time. Consequently, builders and contractors increasingly recognize HDPE pipes as a reliable and cost-effective choice for modern plumbing projects.

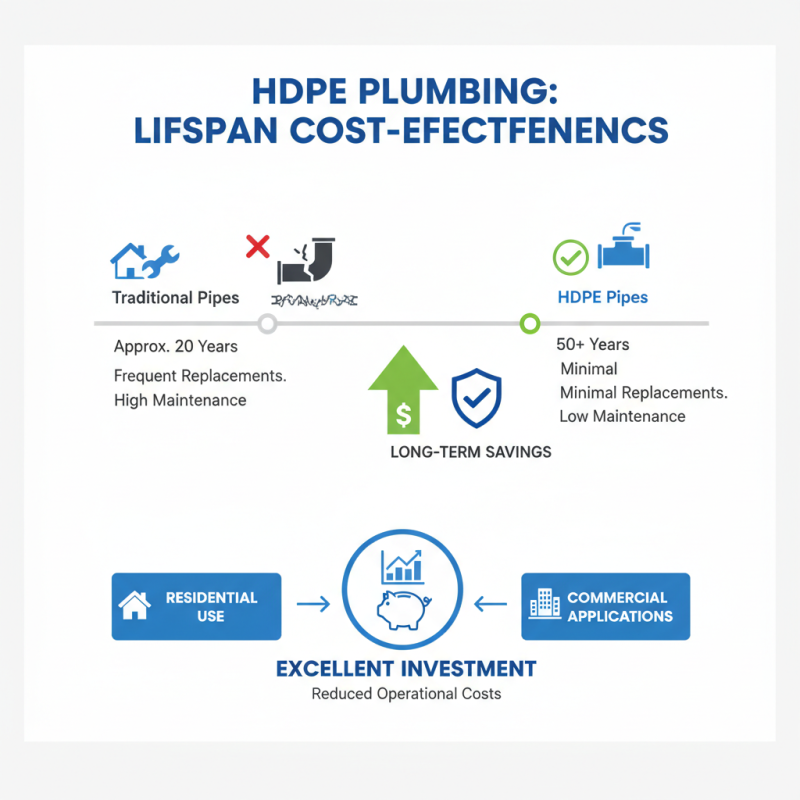

Cost-Effectiveness of HDPE Pipes Over Their Lifespan

When considering materials for plumbing projects, HDPE (High-Density Polyethylene) pipes stand out for their remarkable cost-effectiveness over their lifespan. Unlike traditional materials, HDPE pipes have a long life expectancy, often exceeding 50 years. This longevity means fewer replacements and lower long-term costs, making them an excellent investment for both residential and commercial applications. Additionally, HDPE pipes require minimal maintenance, which can further reduce operational costs.

One important tip when using HDPE piping is to ensure that proper installation techniques are followed. Poor installation can lead to early failures, negating the cost benefits. Furthermore, if you're working on a large-scale project, consider the advantages of bulk purchasing. Buying in larger quantities can significantly lower the overall pipe cost, making it even more economically viable.

Another critical factor is the environmental impact of your materials. HDPE pipes are recyclable, and their production emits fewer greenhouse gases compared to traditional materials. Opting for such eco-friendly options not only contributes to sustainability but often leads to savings in disposal costs at the end of the pipe's lifecycle. By choosing HDPE, you embrace a forward-thinking approach that benefits both your finances and the planet.

Environmental Benefits of Using HDPE for Water Distribution

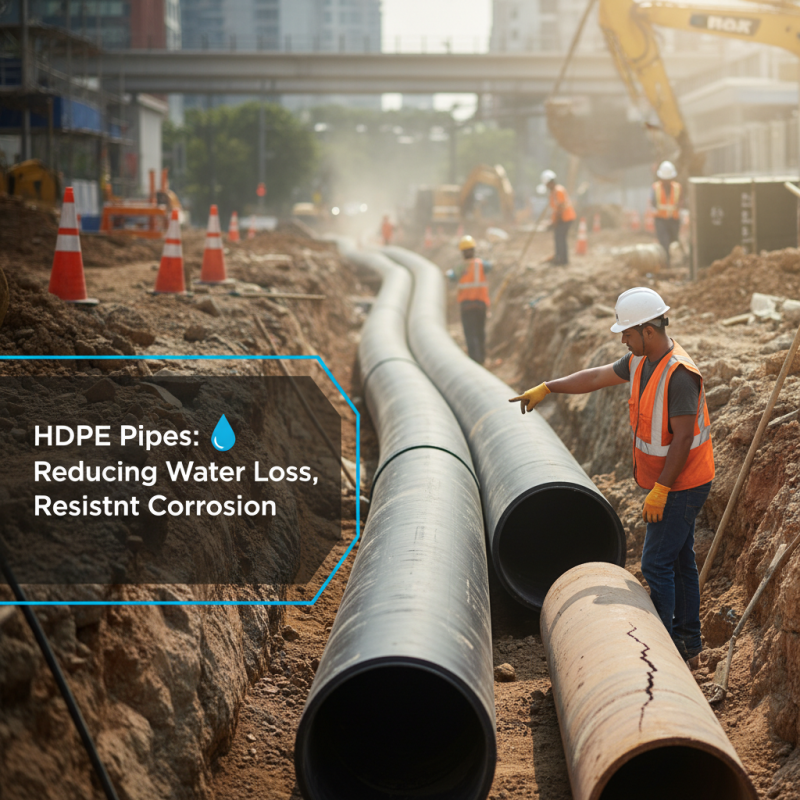

HDPE, or high-density polyethylene, is increasingly recognized for its significant environmental advantages in water distribution systems. One of the primary benefits of using HDPE pipes lies in their ability to reduce water loss. Traditional piping materials often suffer from corrosion and leaks over time, leading to significant waste and resource depletion. In contrast, HDPE’s resistance to corrosion and low permeation rates ensure a more reliable and efficient delivery of water, contributing to sustainable resource management.

Additionally, HDPE is fully recyclable, which positions it as a more environmentally friendly option compared to many conventional materials. By choosing HDPE for plumbing projects, not only are users minimizing the carbon footprint associated with the production and maintenance of water pipes, but they are also supporting a circular economy. The ability to reuse HDPE products at the end of their lifespan encourages responsible waste management practices and reduces the burden on landfills, aligning plumbing projects with broader environmental sustainability goals. Moreover, the lightweight nature of HDPE makes transportation and installation easier and more energy-efficient, further enhancing its ecological appeal.

Installation and Maintenance Considerations for HDPE Pipes

When considering HDPE pipes for your plumbing project, understanding installation and maintenance is crucial. HDPE (High-Density Polyethylene) pipes offer flexibility and resistance to corrosion, making them an excellent choice for both underground and above-ground applications. During installation, it's essential to ensure that the trench is excavated properly, providing a stable base that minimizes the risk of shifting or settling. Additionally, joining methods such as heat fusion or mechanical fittings should be chosen based on the specific requirements of your project, ensuring a seamless and robust connection.

Tips: Always check local regulations and guidelines before starting your installation, as they can dictate specific materials and methods to be used in your area.

Maintenance of HDPE pipes is relatively straightforward, but regular inspections are necessary to identify and address potential issues such as leaks or blockages. Unlike traditional piping materials, HDPE is less prone to rust and scaling, which means fewer maintenance concerns. Nonetheless, it's advisable to use non-destructive testing methods to monitor the integrity of the pipes over time and to keep an eye on the surrounding soil conditions that might affect the pipes' performance.

Tips: Schedule routine visual inspections and maintain clear access to the pipes to facilitate any necessary repairs or upgrades in the future.

Related Posts

-

Exploring the Benefits of HDPE Pipe: Why Its Durability and Chemical Resistance Make It an Industry Standard

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions

-

2025's Top 5 HDPE Plastic Pipe Innovations for Efficient Water Management

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

-

Why Poly Water Pipe is the Best Solution for Your Irrigation Needs