-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

In the evolving landscape of infrastructure development, the choice of materials for sewer systems is of utmost importance. High-Density Polyethylene (HDPE) sewer pipes have increasingly garnered attention due to their superior properties, making them a preferred option for many civil engineering projects. According to a recent report from the American Society of Civil Engineers, the use of HDPE for sewer systems has seen a significant uptick, with projected growth in demand driven by its lightweight design, corrosion resistance, and longevity compared to traditional materials like PVC and concrete.

Selecting the best HDPE sewer pipe for your project requires a keen understanding of various factors, including the specific requirements of the project site, the environmental conditions, and the long-term performance expectations. The Plastics Pipe Institute reports that HDPE pipes can last over 100 years in service, significantly outlasting other materials, which frequently need replacement within several decades. Furthermore, their flexibility allows for ease of installation, particularly in challenging terrains, enabling more efficient trenching and reducing the overall labor costs.

As we delve into the specifics of choosing the ideal HDPE sewer pipe, it is essential to consider not only the engineering attributes but also the sustainability aspect associated with using HDPE materials. With a focus on reducing carbon footprints and enhancing system resiliency, the correct selection of HDPE sewer pipes can lead to a more sustainable and cost-effective infrastructure solution for the future.

Understanding HDPE Sewer Pipes: Key Properties and Benefits

When selecting the best HDPE sewer pipe for your project, understanding its key properties and benefits is crucial. High-Density Polyethylene (HDPE) is known for its excellent chemical resistance, flexibility, and durability, making it an ideal choice for sewer systems. HDPE pipes can withstand harsh environmental conditions, reducing the risk of leaks or failures over time. Their lightweight nature also simplifies installation, allowing for easier handling and transportation compared to traditional materials like PVC or concrete.

Moreover, the flexibility of HDPE allows it to adapt to ground movements, which is particularly advantageous in areas prone to seismic activity or soil shifts. Additionally, its smooth interior surface enhances flow efficiency while minimizing the buildup of debris, leading to lower maintenance costs over the lifespan of the system. These properties, combined with the material's recyclability, position HDPE sewer pipes as a sustainable option for modern infrastructure projects, appealing to eco-conscious stakeholders seeking reliable and environmentally friendly solutions.

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

This chart illustrates the key properties of HDPE sewer pipes based on different criteria crucial for selecting the best option for your project, including durability, flexibility, and resistance to chemicals.

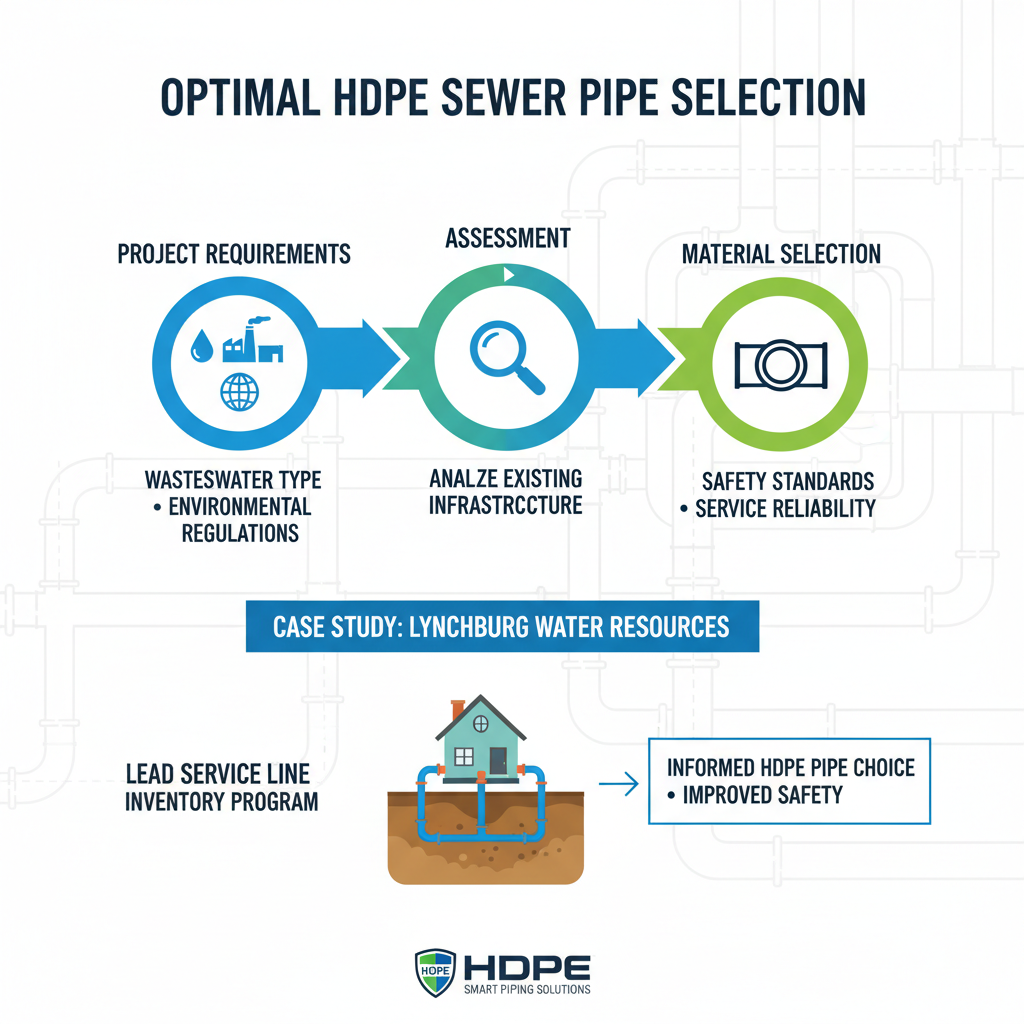

Identifying Project Requirements for Sewer Pipe Selection

When selecting the best HDPE sewer pipe for any project, it is crucial to identify the specific requirements of the project. Factors such as the nature of the wastewater being conveyed, the environmental conditions, and regulatory compliance must be thoroughly assessed. For instance, Lynchburg Water Resources is implementing its Lead Service Line Inventory Program, which emphasizes the importance of understanding the materials in use. This approach highlights how analyzing the existing infrastructure can guide the selection of appropriate sewer piping that meets safety standards and improves service reliability.

Additionally, ongoing projects like the Tysons Wastewater Conveyance Systems Modifications illustrate the significance of detailed design and planning in sewer pipe selection. The acquisition of easements and permitting processes for gravity sewers and force mains require careful consideration of both technical specifications and project timelines. By leveraging advanced technologies such as machine learning, as seen in Raleigh Water's initiatives, agencies can preemptively identify potential system failures, thereby ensuring that the chosen HDPE sewer pipes will be durable and efficient under expected operational conditions.

Factors to Consider When Choosing HDPE Sewer Pipe Size and Diameter

When selecting the best HDPE sewer pipe for your project, understanding the size and diameter is crucial. The HDPE pipe market is anticipated to grow significantly, projected to reach USD 25.68 billion by 2029. This growth underscores the rising importance of material choices in infrastructure projects, particularly in the context of compliance with regulations and standards set forth for sanitary designs.

When determining the appropriate size and diameter for HDPE sewer pipes, consider the flow requirements of your project. A pipe’s diameter affects its capacity to handle varying volumes of wastewater. Additionally, it is essential to evaluate the soil conditions and the potential for future expansion when choosing pipe dimensions. Industry standards emphasize that the chosen pipe must efficiently manage anticipated loads to avoid costly failures or repairs down the road.

Tips for selecting the right HDPE sewer pipe include:

- Conducting thorough hydraulics calculations to determine the correct diameter based on flow rates and pressure requirements.

- Considering longevity and resistance to environmental factors when selecting materials.

- Consulting industry guidelines and best practices to ensure your design adheres to current regulations and standards, which can significantly impact the overall performance and durability of your pipe system.

Comparing HDPE Sewer Pipes with Other Materials for Durability

When evaluating the best materials for sewer pipe projects, HDPE (High-Density Polyethylene) pipes offer significant advantages over traditional materials such as PVC and concrete. The HDPE pipes market is on a robust growth trajectory, projected to reach USD 25.68 billion by 2029. This growth is fueled by increasing infrastructure investments and a shift toward sustainable construction practices. Notably, HDPE pipes are known for their superior durability, resistance to corrosion, and flexibility, making them ideal for various soil conditions and environmental factors.

In comparison, conventional materials like PVC may lack the necessary strength and longevity for challenging applications. Studies indicate that HDPE's sustainability profile is also a key differentiator. The global HDPE pipes market was valued at USD 23.99 billion in 2024 and is expected to grow from USD 25.24 billion in 2025 to a remarkable USD 37.96 billion by 2033. These statistics underscore the ongoing shift in preference towards HDPE, driven by its capacity to withstand harsh conditions while minimizing environmental impact, thereby securing its position as a leading choice for modern sewer systems.

2025 How to Choose the Best HDPE Sewer Pipe for Your Project - Comparing HDPE Sewer Pipes with Other Materials for Durability

| Material | Durability (Years) | Corrosion Resistance | Installation Cost ($ per foot) | Maintenance Required (Frequency) |

|---|---|---|---|---|

| HDPE | 50+ | Excellent | $4 - $6 | Low (Every 10 years) |

| PVC | 25 - 40 | Good | $3 - $5 | Moderate (Every 5 years) |

| Concrete | 50 - 100 | Poor | $6 - $9 | High (Every 2 years) |

| Cast Iron | 50 - 100 | Fair | $10 - $15 | Moderate (Every 5 years) |

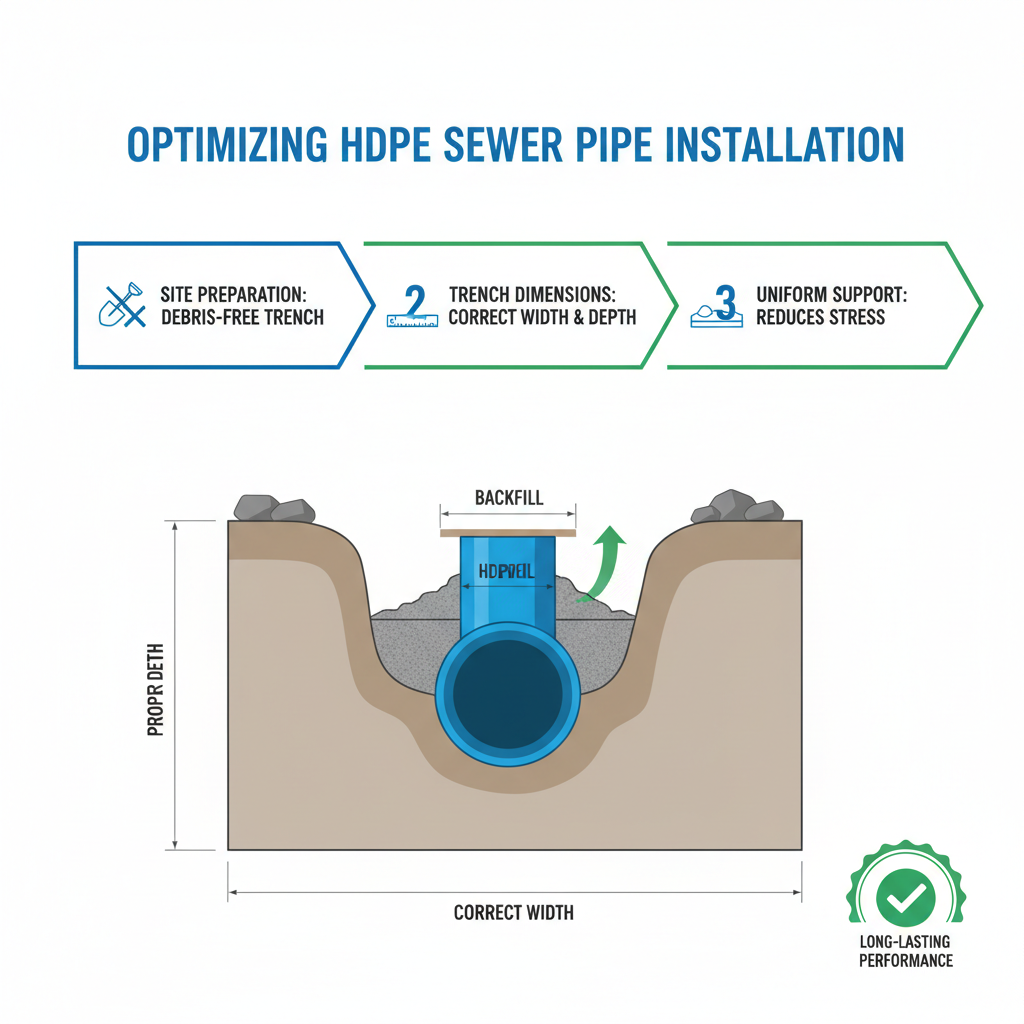

Installation Practices for Optimizing HDPE Sewer Pipe Performance

When installing HDPE sewer pipes, proper installation practices are crucial for optimizing their performance and longevity. First and foremost, site preparation is essential. This includes ensuring that the trench is free of debris and large rocks, which can damage the pipe. Additionally, maintaining the correct trench width and depth is vital to facilitate proper bedding and avoid unnecessary stress on the pipe. A well-prepared trench allows for uniform support, reducing the risk of deformation over time.

Moreover, the use of appropriate jointing methods greatly influences the performance of HDPE sewer pipes. Typical joining techniques include butt fusion, electrofusion, and mechanical joints. Each method has specific requirements and benefits, so it’s important to follow manufacturer guidelines closely. Furthermore, testing the joints after installation can prevent leaks and ensure a tight seal, contributing to overall system integrity. Attention to detail during installation, including alignment and backfilling procedures, significantly enhances the operational efficiency of the sewer system, ultimately extending the lifespan of HDPE pipes.

Related Posts

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions

-

2025's Top 5 HDPE Plastic Pipe Innovations for Efficient Water Management

-

Understanding the Essential Role of PE Pipe Fittings in Modern Plumbing Systems

-

Exploring the Benefits of HDPE Pipe: Why Its Durability and Chemical Resistance Make It an Industry Standard

-

Top 5 Essential Tips for Choosing the Best PE Fitting for Your Plumbing Needs