-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

Best Ways to Use Poly Water Pipe for Your Projects?

Poly water pipe has transformed water management in various industries. According to industry reports by the Plastic Pipe Institute, the demand for poly water pipes has surged by 30% over the last five years. This material is lightweight yet incredibly durable, making it an ideal choice for diverse applications, from agricultural irrigation to municipal water systems. With advancements in technology, poly water pipe installations are becoming more efficient and cost-effective.

Despite its advantages, not all users are fully aware of the best practices. Some projects suffer from improper installation techniques, which can lead to leaks and costly repairs. Noticing the early signs of wear and damage can save significant expenses later. It’s crucial to ensure the appropriate sizing and fittings when working with poly water pipe. A recent survey indicated that 25% of installations failed due to improper material selection.

The versatility of poly water pipe is notable—it adapts well to various environments. However, not every project benefits from its use, and professionals must analyze specific project needs. Understanding local soil conditions and climate factors is essential. While poly water pipe offers advantages, users should recall that proper education and planning are imperative for successful outcomes.

Understanding Poly Water Pipe: Types and Specifications

Poly water pipes are widely used in various projects due to their versatility and durability. Understanding the types of poly pipes will help you choose the right one for your needs. There are mainly two types: High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE). HDPE pipes are strong and resistant to impact, making them suitable for underground installations. LDPE pipes are more flexible and lightweight, ideal for irrigation and low-pressure applications.

When selecting poly water pipes, consider the specifications. The diameter, wall thickness, and pressure rating are essential. A larger diameter allows greater flow, but it may also be harder to handle. Wall thickness affects durability, particularly in harsh environments. Make sure to assess the pressure rating to ensure it meets the demands of your project. Many people overlook this detail, leading to issues later on.

Additionally, installation can be tricky. Using the right fittings is critical. Improper connections can lead to leaks. It’s vital to evaluate your project thoroughly and foresee potential problems. Everyone makes mistakes, even seasoned contractors. Learning from these challenges will make you more experienced. Remember, the right approach can save both time and resources in the long run.

Best Ways to Use Poly Water Pipe for Your Projects

| Type of Poly Water Pipe | Diameter (inches) | Length (feet) | Applications | Pressure Rating (PSI) |

|---|---|---|---|---|

| Polyethylene (PE) | 1 | 100 | Irrigation, water supply | 160 |

| High-Density Polyethylene (HDPE) | 2 | 200 | Municipal water, gas distribution | 125 |

| Linear Low-Density Polyethylene (LLDPE) | 4 | 50 | Drip irrigation, slurry transport | 80 |

| Schedule 40 Poly Pipe | 3 | 300 | Swimming pools, landscaping | 200 |

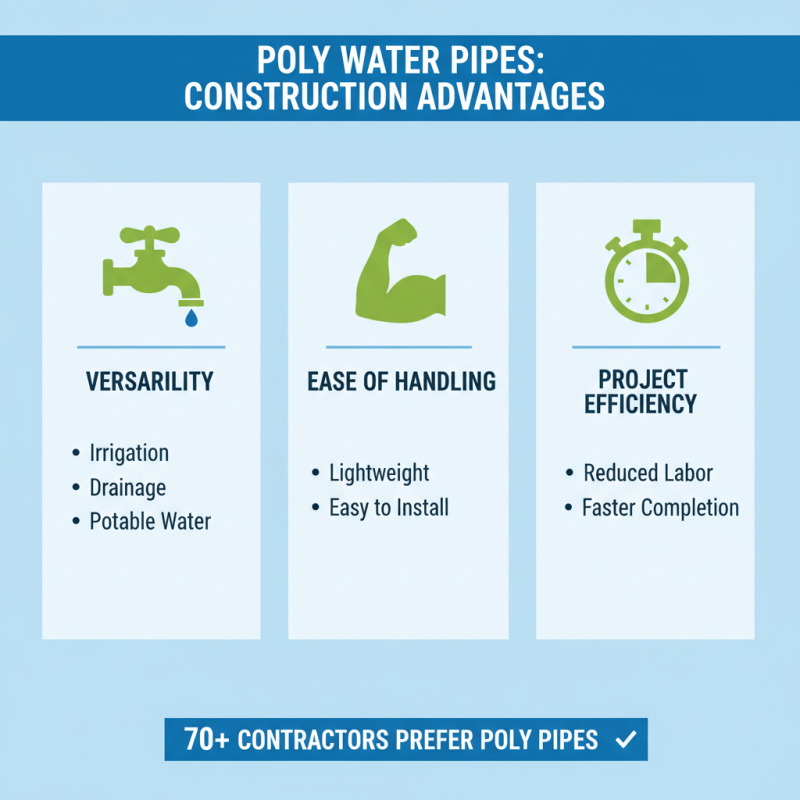

Advantages of Using Poly Water Pipe in Construction Projects

Poly water pipe offers several advantages that make it an ideal choice for construction projects. One of the biggest benefits is its versatility. It can be used in various applications, including irrigation, drainage, and potable water systems. According to industry reports, over 70% of contractors prefer poly pipes for their light weight and ease of handling. This choice translates to reduced labor costs and quicker project completion times.

Durability is another strong point. Poly water pipes resist corrosion and are less likely to crack compared to traditional piping. Research indicates that they can last over 50 years with proper installation. However, some contractors encounter challenges with joints and fittings, which may require careful attention during setup. A common issue is the potential for improper sealing, which could lead to leaks down the line.

Additionally, poly pipes are more environmentally friendly than metal alternatives. They require less energy to produce and can be recycled at the end of their life cycle. Yet, not all projects may find poly pipes suitable. In high-pressure systems, their performance can be questionable. This requires engineers to weigh the pros and cons carefully. Understanding these trade-offs is essential for making informed decisions in any project.

Best Installation Practices for Poly Water Pipe

When it comes to installing poly water pipes, proper preparation is crucial. Start by choosing an appropriate trench depth. Generally, a depth of at least 12 inches is recommended to ensure the pipes are protected from external pressures and temperature changes. The trench should also be wide enough to allow easy access for installation and maintenance. Level the bottom of the trench to avoid any foundation issues later. Everyone makes mistakes in this step, thinking they can just lay pipes anywhere. But this can lead to unnecessary complications.

Next, ensure that you use the right fittings. Poly water pipes can be joined using heat fusion or mechanical fittings. It’s essential to follow proper procedures during installation. Many installers underestimate the importance of clean pipe ends. If debris gets inside, it may cause leaks over time. Carefully inspect the pipes before joining them together. Pay attention to the temperature, as it can affect the fusing process. Mistakes here can lead to poor connections.

Finally, backfill the trench with care. Avoid using sharp rocks or debris that could damage the pipes. Layering the soil gently can help protect your installation. People often rush this process, leading to uneven pressure on the pipes. Inadequate backfilling can also cause settling issues in the future. Take your time to ensure everything is done right. Your efforts now will pay off later in reliability and performance.

Best Installation Practices for Poly Water Pipe

Common Applications of Poly Water Pipe in Various Industries

Poly water pipe has become a popular choice in various industries due to its versatility and durability. One common application lies in agriculture. Farmers often use this type of pipe for irrigation systems. It efficiently transports water, ensuring crops receive the hydration they need. However, improper installation can lead to leaks. Regular checks are essential.

Another significant use is in landscaping. Gardeners appreciate how lightweight and flexible poly water pipe is for watering gardens and flower beds. It can navigate around plants easily. Yet, exposure to sunlight can degrade the material over time. Using protective covers may extend its lifespan.

In construction, poly water pipe is prevalent for drainage systems. It effectively channels excess water away from foundations. Builders must ensure proper grading to prevent water pooling. Otherwise, it can compromise the structure. Each application demands careful consideration to avoid common pitfalls.

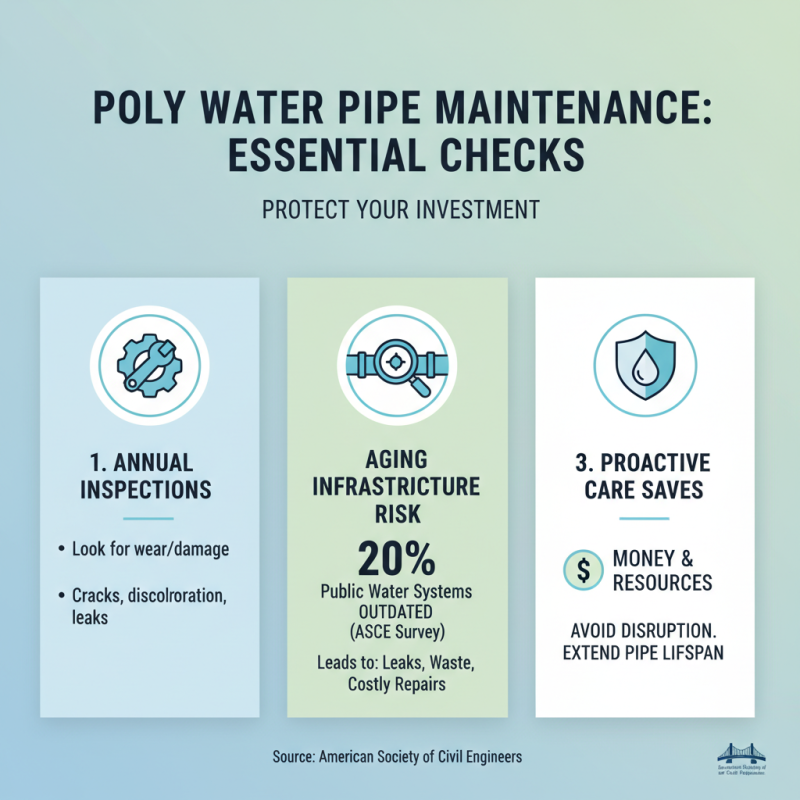

Maintenance Tips for Long-Lasting Poly Water Pipe Systems

When it comes to maintaining poly water pipe systems, regular checks are essential. A survey from the American Society of Civil Engineers shows that around 20% of public water systems are outdated. Aging infrastructure can lead to leaks, waste, and costly repairs. To avoid these issues, inspect your pipes annually. Look for signs of wear or damage, such as cracks or discoloration.

Tip: Clean the pipes regularly. Sediment build-up can weaken the structure over time. Flushing the system can help maintain water flow and quality.

Proper installation is key. A report from the International Association of Plumbing and Mechanical Officials suggests that improperly installed pipes can decrease system efficiency by up to 30%. Ensure joints are sealed correctly. And don't forget to insulate pipes in cold climates to prevent freezing.

Tip: Apply protective coatings to prolong lifespan. This can improve resistance to UV rays and corrosion.

Taking these steps does require effort. It can be easy to overlook pipe maintenance. However, investing time now can prevent larger problems later. Neglecting these tasks might lead to expensive interruptions in your water system.

Related Posts

-

What is Poly Water Pipe? Benefits, Uses, and Installation Guide

-

Top Benefits of Using Poly Water Pipe in 2025 for Efficient Water Management

-

Top 10 Benefits of High Density Polyethylene Pipe for Industrial Use

-

Ultimate Guide to Poly Pipe Sizes for Your Next Project

-

Top 5 Pressure Pipe Fittings You Need for Your Next Plumbing Project

-

Why Poly Water Pipe is the Best Solution for Your Irrigation Needs