-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

Top 10 Benefits of High Density Polyethylene Pipe for Industrial Use

In the ever-evolving landscape of industrial infrastructure, the adoption of high density polyethylene pipe (HDPE) has gained remarkable attention. Renowned industry expert Dr. Emily Thompson recently stated, "The efficiency and durability offered by high density polyethylene pipe revolutionize traditional piping systems, providing unmatched performance in a variety of applications." As industries seek sustainable and cost-effective solutions, HDPE stands out due to its remarkable strength-to-density ratio and resistance to corrosion, ensuring longevity and reduced maintenance costs.

The advantages of high density polyethylene pipe are numerous, making it an ideal choice for various industrial applications, including water distribution, wastewater management, and chemical handling. Its flexibility and lightweight characteristics facilitate easier installation compared to conventional materials, ultimately leading to reduced labor costs and downtime. Furthermore, its resilience against environmental stressors contributes to a more reliable and efficient infrastructure, ensuring that industrial operations run smoothly. As we explore the top ten benefits of high density polyethylene pipe for industrial use, it becomes clear that this innovative piping solution is not just a trend but a fundamental shift towards more effective industrial practices.

Advantages of High Density Polyethylene Pipe in Industrial Applications

High Density Polyethylene (HDPE) pipe has gained significant traction in various industrial applications due to its remarkable properties and advantages. One of the primary benefits of HDPE pipe is its exceptional resistance to corrosion, which makes it ideal for environments where exposure to chemicals and moisture is prevalent. Unlike traditional metal pipes that can erode or rust, HDPE pipe maintains its integrity over time, ensuring durability and reducing the need for frequent replacements. This characteristic not only lowers maintenance costs but also enhances the reliability of the entire piping system.

Another advantage of HDPE pipe lies in its flexibility and lightweight nature. This makes installation easier and more efficient, as it can be maneuvered through tight spaces and fitting designs. Additionally, the high tensile strength of HDPE allows for the construction of longer pipe lengths without joints, which further minimizes potential leak points. Combining these features results in a lower overall installation time and cost, making HDPE an attractive option for industries looking to optimize their operations while ensuring long-lasting performance in their piping systems.

Durability and Long Lifespan of HDPE Pipes for Industrial Use

High-density polyethylene (HDPE) pipes have gained popularity in industrial applications due to their remarkable durability and long lifespan. These pipes are resistant to corrosion, meaning they do not degrade over time when exposed to various chemicals encountered in industrial settings. This inherent resistance ensures that HDPE pipes maintain their structural integrity longer than traditional materials, leading to reduced maintenance costs and lower replacement frequency. In addition, HDPE’s flexibility allows it to withstand environmental stresses, making it an ideal choice for projects involving shifts in temperature or ground movement.

When selecting HDPE pipes, keep in mind a few essential tips to maximize their longevity. First, ensure proper installation by working with experienced professionals who understand the specific requirements for HDPE. Incorrect installation can lead to issues like leaks or damage. Additionally, consider the operating conditions—factors such as temperature fluctuations and exposure to specific chemicals can impact the lifespan of the pipes. Regular inspection and maintenance are also vital; while HDPE is low maintenance, staying proactive can help address potential issues before they escalate.

By capitalizing on the strengths of HDPE pipes, industries can enjoy a reliable infrastructure solution that stands the test of time. As they continue to outlast many conventional pipe materials, businesses can focus on growth and efficiency, knowing that their piping systems are built to endure.

Cost-Effectiveness of High Density Polyethylene Pipe Solutions

High Density Polyethylene (HDPE) pipes are increasingly recognized for their cost-effectiveness in industrial applications. According to a report by the Plastics Industry Association, HDPE pipes can reduce installation costs by up to 30% compared to traditional materials such as metal or concrete. This reduction largely stems from their lightweight nature, which allows for easier transportation and installation, ultimately leading to lower labor costs. Furthermore, the long lifespan of HDPE pipes, often exceeding 50 years, adds significant savings, as fewer replacements are needed over time.

Tips: When considering HDPE for your next project, it's essential to assess the total cost of ownership rather than just initial prices. Conduct a lifecycle analysis to ensure you capture all associated costs, including maintenance and replacement.

Additionally, the resistance of HDPE pipes to corrosion and chemicals minimizes the need for expensive protective coatings or linings, which is a common requirement for pipes made from other materials. A study by the American Society of Civil Engineers indicated that HDPE's durability can result in a decrease in operational disruptions and maintenance costs by as much as 25%. Choosing HDPE can thus provide industries with a reliable, low-maintenance pipe system that supports long-term financial planning.

Tips: Always consult with a qualified engineer when designing your pipeline systems to ensure you maximize the benefits of HDPE, particularly in harsh environmental conditions.

Environmental Benefits of Using HDPE Pipes in Industrial Projects

High Density Polyethylene (HDPE) pipes are increasingly favored in industrial projects for their numerous environmental benefits. One of the primary advantages is their recyclability. Unlike traditional piping materials, HDPE can be recycled at the end of its life cycle, significantly reducing waste in landfills and promoting a circular economy. This sustainable approach not only conserves resources but also diminishes the environmental footprint associated with manufacturing new pipes.

Moreover, HDPE pipes are known for their durability and resistance to corrosion and chemical damage. This longevity means that fewer replacement pipes are needed over time, leading to decreased material consumption and lower emissions during production. Additionally, HDPE's lightweight nature allows for easier transportation and installation, resulting in reduced fuel consumption and greenhouse gas emissions during project execution. As industries continue to prioritize sustainable practices, the adoption of HDPE pipes presents a practical solution that aligns with environmental stewardship goals.

Versatility and Adaptability of High Density Polyethylene in Various Industries

High Density Polyethylene (HDPE) pipe has emerged as a cornerstone of modern industrial applications, thanks to its remarkable versatility and adaptability across various sectors. The 2021 report by MarketsandMarkets indicates that the HDPE pipe market is projected to grow from USD 9.3 billion in 2021 to USD 13.6 billion by 2026, reflecting an increasing acceptance of this material due to its advantageous properties. Across industries such as agriculture, construction, and water management, HDPE pipes are favored for their resistance to corrosion and chemical exposure, making them an ideal choice for carrying various fluids without concerns of degradation.

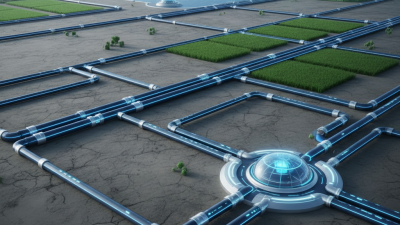

In the agricultural sector, for instance, HDPE pipes are extensively utilized for irrigation systems, ensuring efficient water conveyance with minimal leakage. The International Irrigation Association highlights that the use of HDPE in irrigation can save up to 30% more water compared to traditional systems, optimizing resource allocation in regions where water scarcity is a pressing issue. Furthermore, in construction, HDPE pipes are increasingly being incorporated into drainage systems and underground utilities due to their lightweight nature and durability, which allows for easier handling and installation. The material's flexibility makes it suitable for varying terrains and conditions, enhancing the resiliency of infrastructure projects.

Moreover, HDPE's adaptability extends into emerging fields such as renewable energy, where it is used in the construction of wind farms and solar energy installations. It is reported that HDPE pipes can withstand extreme temperatures and pressures, which is crucial for supporting the modern energy infrastructure. With these multifaceted applications and continuous innovations in production techniques, the HDPE pipe industry is poised to maintain its growth trajectory and fulfill the diverse needs of modern industrial environments.

Related Posts

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

2025's Top 5 HDPE Plastic Pipe Innovations for Efficient Water Management

-

Understanding the Advantages of High Density Polyethylene Pipe in Modern Infrastructure Solutions

-

Exploring the Benefits of HDPE Pipe: Why Its Durability and Chemical Resistance Make It an Industry Standard

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

-

Why Choose HDPE Water Pipe for Your Next Plumbing Project?