-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

2025 Top Trends in Plastic Pipework for Efficient Construction Solutions

The construction industry is undergoing a significant transformation as it seeks to enhance efficiency and sustainability in building practices. One of the most notable advancements is in the realm of plastic pipework, which has become a cornerstone of modern construction solutions. With a projected market growth rate of 7.5% annually, as cited by the Global Plastic Pipe Market Report, the shift towards plastic materials reflects a broader trend towards lightweight, durable, and cost-effective building solutions.

Plastic pipework, particularly those made from high-density polyethylene (HDPE) and polyvinyl chloride (PVC), is increasingly preferred for its superior resistance to corrosion, ease of installation, and long lifespan. According to the Plastics Industry Association, plastic pipes now account for over 60% of the market share in plumbing and drainage systems. This shift not only reduces labor costs but also minimizes waste generation, making it an attractive option for environmentally-conscious builders.

As we look towards 2025, the adoption of plastic pipework is expected to be driven by key trends such as innovation in material science, increased demand for sustainable infrastructure, and advancements in manufacturing processes. Emphasizing efficiency and resilience, these trends position plastic pipework as a pivotal component in building the infrastructure of the future, highlighting its critical role in facilitating effective construction solutions.

Innovative Materials Driving the Future of Plastic Pipework in Construction

The future of plastic pipework in construction is being shaped by innovative materials that enhance efficiency and sustainability. Recent industry reports predict that the global plastic pipes market could reach approximately $91 billion by 2025, driven by these advancements. New materials such as high-density polyethylene (HDPE) and polyvinyl chloride (PVC) are increasingly being adopted due to their lightweight properties, resistance to corrosion, and low installation costs. According to a study by MarketsandMarkets, these materials have driven a 30% increase in demand over the last five years, underpinning their significance in modern construction practices.

When considering materials for your next project, it's essential to look for those that not only meet performance standards but also contribute to energy savings. For instance, HDPE pipes have been shown to reduce water loss by up to 50% compared to traditional materials, contributing significantly to overall project efficiency.

Tip: Always assess the lifecycle impact of the materials you choose. Opt for recycled plastics or materials that can be easily repurposed to further reduce environmental footprints. This not only enhances sustainability but may also qualify your project for green building certifications.

2025 Top Trends in Plastic Pipework for Efficient Construction Solutions

Sustainability Trends: Eco-Friendly Practices in Plastic Pipe Manufacturing

The increasing awareness of environmental issues has propelled the plastic pipe manufacturing industry to adopt more sustainable practices. A key trend is the use of recycled materials in the production of plastic pipes, which significantly reduces waste and conserves resources. Manufacturers are now incorporating post-consumer recycled plastics, allowing for a circular economy that minimizes the demand for virgin materials. This shift not only reduces the carbon footprint but also supports the overall movement towards sustainable construction solutions.

In addition to using recycled content, eco-friendly production methods are gaining traction. Advanced technologies such as energy-efficient extrusion processes and the use of biodegradable additives are enhancing the sustainability of plastic pipes. These innovations not only decrease energy consumption during manufacturing but also ensure that end products are less harmful to the environment. As the construction industry seeks to meet stringent sustainability goals, the adoption of these eco-friendly practices in plastic pipe manufacturing will play a vital role in facilitating efficient and responsible building solutions.

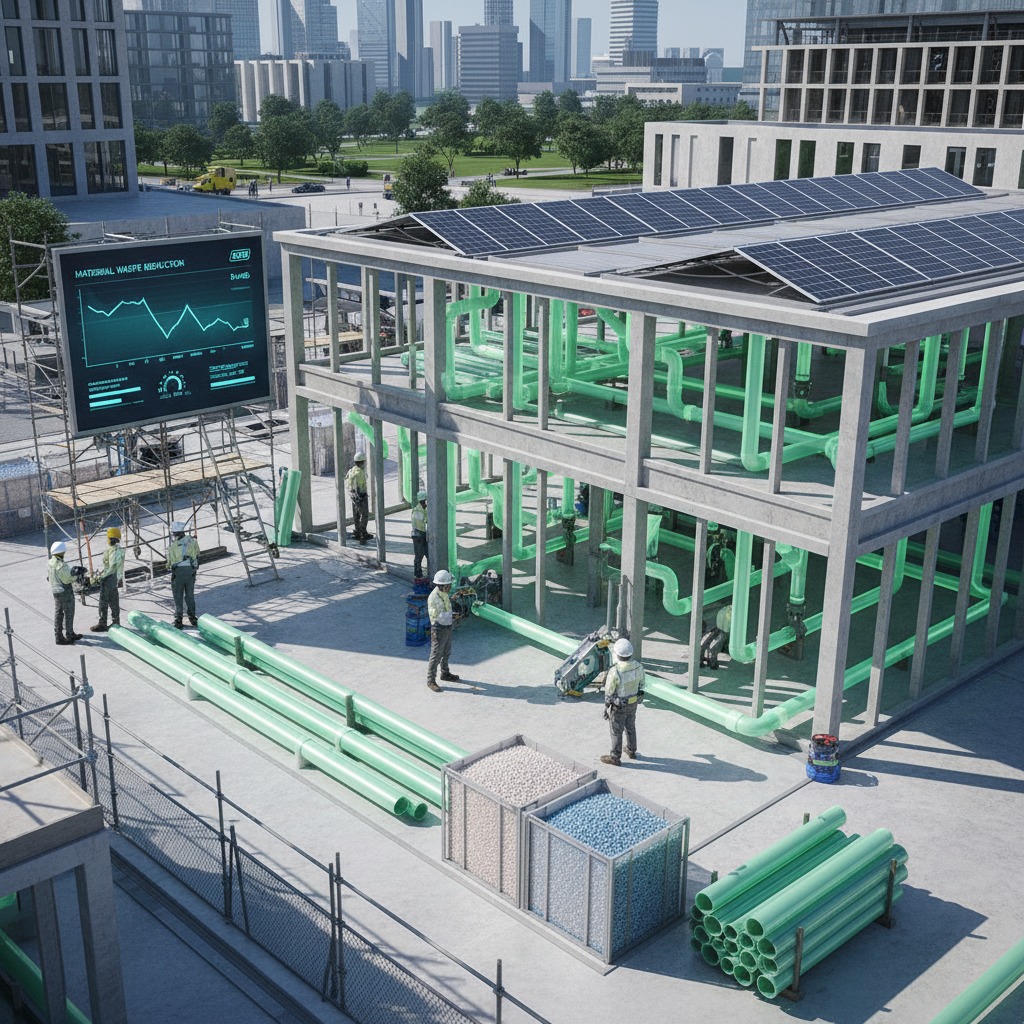

Smart Technology Integration: Enhancing Efficiency in Pipe Installation

The integration of smart technology in the installation of plastic pipework is revolutionizing the construction industry, significantly enhancing efficiency and reducing operational costs. According to a report by IBISWorld, the global plastic pipe market is expected to grow at a CAGR of 6.4% from 2021 to 2026, with smart technologies playing a pivotal role in this expansion. Innovations such as IoT-enabled sensors and automated systems allow for real-time monitoring and adjustments during installation, resulting in a more streamlined process and reduced material waste.

Moreover, the adoption of Building Information Modeling (BIM) in pipe installation facilitates meticulous planning and coordination among various stakeholders. A study by McKinsey indicates that projects utilizing BIM can see productivity improvements of up to 20%. This not only speeds up the installation process but also ensures higher accuracy and reduces the likelihood of costly rework. As the construction sector continues to embrace these advancements, the future of plastic pipework is undoubtedly poised for a transformation that prioritizes smart technology and efficiency.

2025 Top Trends in Plastic Pipework for Efficient Construction Solutions

| Trend | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| Smart Pipe Monitoring | Real-time monitoring systems for water flow and pressure. | Reduces leaks and maintenance costs. | 2025 |

| Augmented Reality (AR) for Installation | Using AR tools to guide pipe installation and repairs. | Increases accuracy and reduces installation time. | 2025 |

| Advanced Material Development | Innovations in plastic materials for enhanced durability. | Increases lifespan of pipes and reduces environmental impact. | 2025 |

| Robotic Installation | Automated systems for laying and connecting pipes. | Increases speed and reduces labor costs. | 2025 |

Market Growth Projections: Analyzing the Plastic Pipe Industry by 2025

The plastic pipe industry is poised for significant growth as we approach 2025, with a projected market size of $37.344 billion, expected to expand to $237.87 billion by 2033. This impressive growth rate of 5.8% CAGR reflects the increasing demand for efficient construction solutions that leverage the benefits of plastic piping systems. Key factors driving this trend include advancements in manufacturing technologies and a rising emphasis on sustainability within construction projects.

In tandem, the flexible plastic packaging market is also witnessing a surge, with an expected growth from $166.53 billion in 2025 to $250.34 billion by 2032, at a CAGR of 6.00%. This aligns closely with the overarching demand for lightweight, durable, and cost-effective materials in various applications across sectors. Furthermore, the thermoplastic pipe market is forecasted to grow from $4.05 billion in 2024 to an astonishing $61.4 billion by 2032, indicating a robust interest in versatile and eco-friendly piping solutions that meet the evolving needs of modern construction practices.

Regulatory Changes Impacting Plastic Pipework Standards and Practices

In 2025, the landscape of plastic pipework is being significantly shaped by regulatory changes that aim to enhance standards and practices within the construction industry. Recent reports indicate that over 60% of industry leaders believe that compliance with updated regulations could lead to a 20% decrease in material waste during construction projects. These standards are primarily driven by heightened environmental concerns and the push for sustainable practices. The revisions focus not only on the materials used in plastic pipework but also on their installation methods, promoting greater efficiency and reducing the carbon footprint associated with traditional plumbing systems.

Moreover, regulatory bodies are increasingly emphasizing the importance of lifecycle assessment in the approval processes for new plastic pipe products. According to the Pipe and Tube Institute, this shift is expected to influence over $1 billion in new capital investment in the sector by 2025, as manufacturers re-evaluate their production techniques to align with stricter compliance guidelines. Ensuring that plastic pipework meets new standards is not just about adhering to regulations; it's also about fostering innovation and contributing to a sustainable future in construction. The industry is poised to embrace these changes, leading to improved safety, performance, and overall project efficiency.

Related Posts

-

Exploring the Versatility of Black Plastic Pipe in Modern Infrastructure Solutions

-

What is a Stormwater Pipe? Understanding Its Role in Drainage Systems

-

2025 How to Choose the Right Pressure Pipe Fittings for Your Plumbing Needs

-

Why Poly Water Pipe is the Best Solution for Your Irrigation Needs

-

Understanding the Role of Polyethylene Pipe in Sustainable Water Management Practices

-

Top 5 Pressure Pipe Fittings You Need for Your Next Plumbing Project