-

Products and Systems

Products and Systems

Vinidex manufacturers and supplies a broad range of products & systems to suit a range of applications.

-

Solutions

Solutions

Vinidex’s products and systems are versatile and can be used in a variety of markets and applications.

- Resources

-

2025 Top Insights on HDPE Plastic Pipe: Benefits, Applications, and Trends

As the demand for efficient and sustainable solutions in infrastructure development grows, the utilization of HDPE plastic pipes continues to gain significant traction across various industries. Known for their exceptional durability, flexibility, and resistance to corrosion, HDPE plastic pipes have established themselves as a reliable choice for a variety of applications, ranging from water supply and drainage systems to telecommunications and gas distribution. This article explores the top insights for 2025 pertaining to the benefits, applications, and emerging trends related to HDPE plastic pipe, shedding light on how this versatile material is reshaping the landscape of modern piping solutions.

With an increasing focus on sustainability, HDPE plastic pipes are often favored for their environmentally friendly properties, including the ability to be recycled and lower carbon footprint during production. Innovations in manufacturing processes and technologies have further enhanced their performance, making them a cost-effective alternative to traditional piping materials. As we delve into the various applications and benefits of HDPE plastic pipes, we also examine the anticipated trends that will shape their future use, offering valuable insights for industry professionals and stakeholders alike.

Overview of HDPE Plastic Pipe: Definition and Key Characteristics

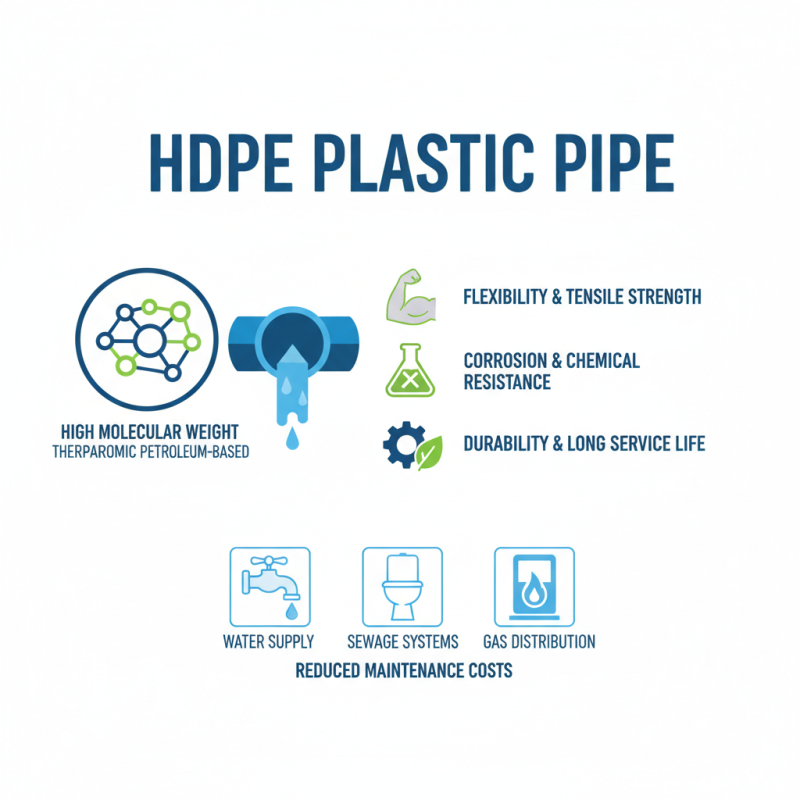

High-Density Polyethylene (HDPE) plastic pipe is a versatile and durable piping solution, widely recognized for its strength and resistance to various environmental factors. Defined by its high molecular weight, HDPE is a thermoplastic made from petroleum. Its key characteristics include excellent tensile strength, flexibility, and resistance to corrosion and chemical damage. These properties make HDPE pipes suitable for a wide range of applications, including water supply, sewage systems, and gas distribution, resulting in prolonged service life and reduced maintenance costs.

One of the distinct advantages of HDPE pipes is their lightweight nature, which facilitates easier installation and transportation compared to traditional materials like metal or concrete. Additionally, the smooth inner surface of HDPE pipes minimizes friction and allows for efficient fluid flow, reducing the energy required to transport liquids through the system. As environmental concerns grow, HDPE's recyclability and reduced carbon footprint during production further enhance its appeal as a sustainable choice for modern infrastructure projects. With the ongoing innovations in manufacturing processes and applications, the demand for HDPE plastic pipes is expected to grow, reflecting their integral role in both industrial and municipal projects.

Key Benefits of HDPE Plastic Pipe in Various Industries

HDPE (High-Density Polyethylene) plastic pipe has become an essential component across various industries due to its numerous benefits. One of the most significant advantages of HDPE is its outstanding resistance to corrosion and chemicals, making it ideal for applications in agricultural, water supply, and industrial sectors. This durability ensures a longer lifespan with lower maintenance costs, offering both economic and environmental benefits. The lightweight nature of HDPE pipes also allows for easier handling and installation, reducing labor time and operational costs.

In addition to its physical properties, HDPE plastic pipe is known for its flexibility and strength, which enable it to withstand various stresses during installation and throughout its service life. This makes it particularly beneficial in areas susceptible to seismic activity or ground movement. Furthermore, HDPE is environmentally friendly, being fully recyclable and requiring fewer resources in its production compared to other pipe materials. As industries increasingly focus on sustainability, the adoption of HDPE pipes aligns well with these goals, contributing to a greener future while meeting the growing demand for efficient and durable piping solutions.

Applications of HDPE Plastic Pipe in Construction and Infrastructure

HDPE plastic pipes have become a cornerstone in modern construction and infrastructure projects due to their numerous advantages. These pipes offer exceptional resistance to corrosion and abrasion, making them ideal for various applications where durability is crucial. In construction, HDPE pipes are widely used for water supply systems, drainage solutions, and sewage management. Their flexibility allows for easy installation in challenging terrains, reducing the need for extensive excavation and thus minimizing disruption to the surrounding environment.

In the realm of infrastructure, HDPE pipes are increasingly utilized for transporting fluids and gases. Their lightweight nature simplifies installation processes and reduces transportation costs. Furthermore, these pipes can endure extreme temperatures and pressure fluctuations, making them suitable for use in both residential and industrial settings. Additionally, the ability to fuse HDPE pipes ensures seamless joints, enhancing the overall integrity of the piping system. This trend towards the adoption of HDPE is reshaping how construction and infrastructure projects are executed, emphasizing sustainability and efficiency for future developments.

| Dimension | Description | Advantages | Applications |

|---|---|---|---|

| Durability | Highly resistant to corrosion and chemical exposure. | Long lifespan and reduced maintenance costs. | Water distribution, wastewater management. |

| Flexibility | Can bend easily without breaking. | Easier installation in complex environments. | Residential plumbing, irrigation systems. |

| Weight | Lightweight compared to traditional materials. | Lower transportation costs and easier handling. | Infrastructure projects, drainage systems. |

| Eco-friendliness | Recyclable and has a lower environmental footprint. | Sustainable choice for future-focused projects. | Green building initiatives, stormwater management. |

| Cost-Effectiveness | Lower initial and long-term cost compared to alternatives. | Improved return on investment for projects. | Public infrastructure, municipal projects. |

Emerging Trends in HDPE Plastic Pipe Technology and Sustainability

The landscape of HDPE plastic pipe technology is rapidly evolving, driven by increasing demands for sustainability and efficiency across various sectors. Recent studies indicate that the global market for HDPE pipes is projected to reach approximately $20 billion by 2025, mainly fueled by their lightweight, durability, and resistance to corrosion. This growing adoption is largely attributed to advancements in manufacturing processes, including the implementation of more energy-efficient production techniques and the incorporation of recycled materials, which significantly enhance the sustainability profile of HDPE pipes.

Emerging trends in the sector include the integration of smart technologies and IoT capabilities within HDPE piping systems. According to the latest market analysis from industry experts, around 30% of new HDPE pipe installations are expected to feature such smart technologies by 2025. This transition not only improves efficiency in resource management but also allows for better tracking and monitoring of pipeline integrity. Furthermore, ongoing innovations in bioplastics suggest a potential shift towards more environmentally friendly raw materials, promising further reductions in environmental impact and fostering an industry-wide commitment to sustainability.

Future Outlook for HDPE Plastic Pipe: Market Growth and Innovations

The future outlook for HDPE plastic pipes is promising, reflecting a significant surge in market growth and innovations. The global HDPE pipe market is projected to reach USD 24.6 billion by 2025, according to a recent industry report. This growth is driven by the increasing demand for efficient and durable infrastructure in various sectors, including water distribution, sewage treatment, and gas supply. Factors such as the lightweight properties of HDPE, resistance to corrosion, and lower installation costs are propelling its adoption over traditional materials.

Innovations in HDPE technology continue to enhance performance and sustainability. Recent developments include the introduction of advanced jointing techniques and enhanced material formulations that improve the longevity and reliability of pipes. With sustainability at the forefront, manufacturers are also focusing on recycling and reducing the environmental impact of production processes. According to the Plastics Industry Association, approximately 30% of HDPE manufactured in 2023 will be sourced from recycled materials, reflecting a significant shift towards a circular economy in the plastics industry.

Tips: When considering HDPE pipes for your project, evaluate the specific operational requirements and local regulations to ensure optimal performance. Additionally, keeping abreast of the latest technological advancements can provide insights into more durable and cost-effective solutions for your infrastructure needs. Regular maintenance and monitoring can further extend the lifespan of HDPE systems, ensuring reliability and efficiency.

2025 Top Insights on HDPE Plastic Pipe: Market Growth and Innovations

This chart illustrates the projected growth in the HDPE plastic pipe market from 2023 to 2025, emphasizing the increasing demand in key application areas.

Related Posts

-

2025 How to Choose the Best HDPE Sewer Pipe for Your Project

-

Top 10 Benefits of Using PVC Water Pipes for Your Plumbing Needs

-

Top 5 Pressure Pipe Fittings You Need for Your Next Plumbing Project

-

Exploring the Versatility of Black Plastic Pipe in Modern Infrastructure Solutions

-

Understanding the Benefits and Applications of HDPE Plastic Pipe in Modern Infrastructure

-

The Ultimate Guide to PVC Pipes and Fittings: Exploring Benefits, Standards, and Market Trends